The global polypropylene container manufacturing industry has achieved unprecedented growth in 2025, driven by increasing demand for durable, versatile, and food-safe packaging solutions across diverse sectors including food service, retail, healthcare, and industrial applications. Polypropylene is used in an extremely wide range of applications, taking advantage of its characteristics. Food containers are a typical application for polypropylene. Of the commercial plastics on the market today, polypropylene is considered one of the safest. It’s FDA-approved for food contact, so you’ll find polypropylene in food containers like those that hold yogurt, cream cheese, and butter products.

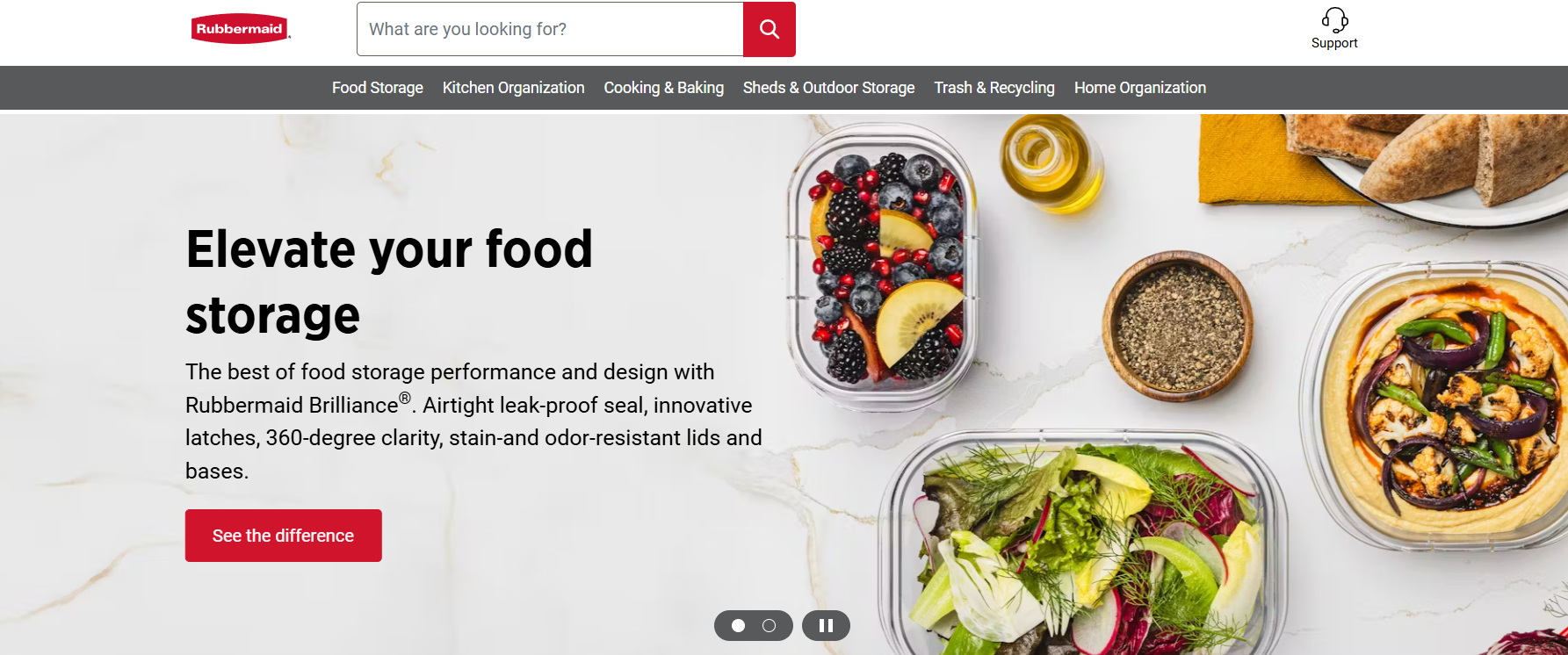

Rubbermaid: American Innovation and Quality Leadership

Rubbermaid stands as North America’s premier polypropylene container manufacturer, leveraging over a century of experience in household products and storage solutions to deliver innovative containers that serve diverse market segments from residential to commercial applications. Rubbermaid is an American manufacturer and distributor of household items. A subsidiary of Newell Brands, it is best known for producing food storage containers and trash cans.

Manufacturing excellence at Rubbermaid encompasses comprehensive product development capabilities that combine advanced material science with consumer-focused design to create polypropylene containers that optimize functionality while maintaining aesthetic appeal and cost competitiveness. Rubbermaid is a leader in home and food storage. Keep your refrigerator, cabinets, garage, and outdoors organized with durable products designed for everyday use.

Innovation leadership focuses on advanced polypropylene formulations that enhance performance characteristics including improved clarity, enhanced impact resistance, and specialized barrier properties that address specific application requirements. Rubbermaid food storage containers are reusable BPA-free products. Choose from glass and plastic food containers with secure lids. The company’s Brilliance line represents breakthrough achievement in polypropylene container technology, offering exceptional stain resistance and clarity retention that maintains aesthetic appeal throughout extended use cycles.

Quality assurance systems encompass comprehensive testing protocols that validate thermal performance, mechanical strength, and food safety compliance while ensuring consistent manufacturing quality across high-volume production requirements. The Rubbermaid – Brilliance was the only plastic food container and lid that showed no signs of damage. The Rubbermaid – Brilliance was the only plastic food container and lid that showed no signs of damage. This superior performance demonstrates Rubbermaid’s commitment to material science excellence and manufacturing precision.

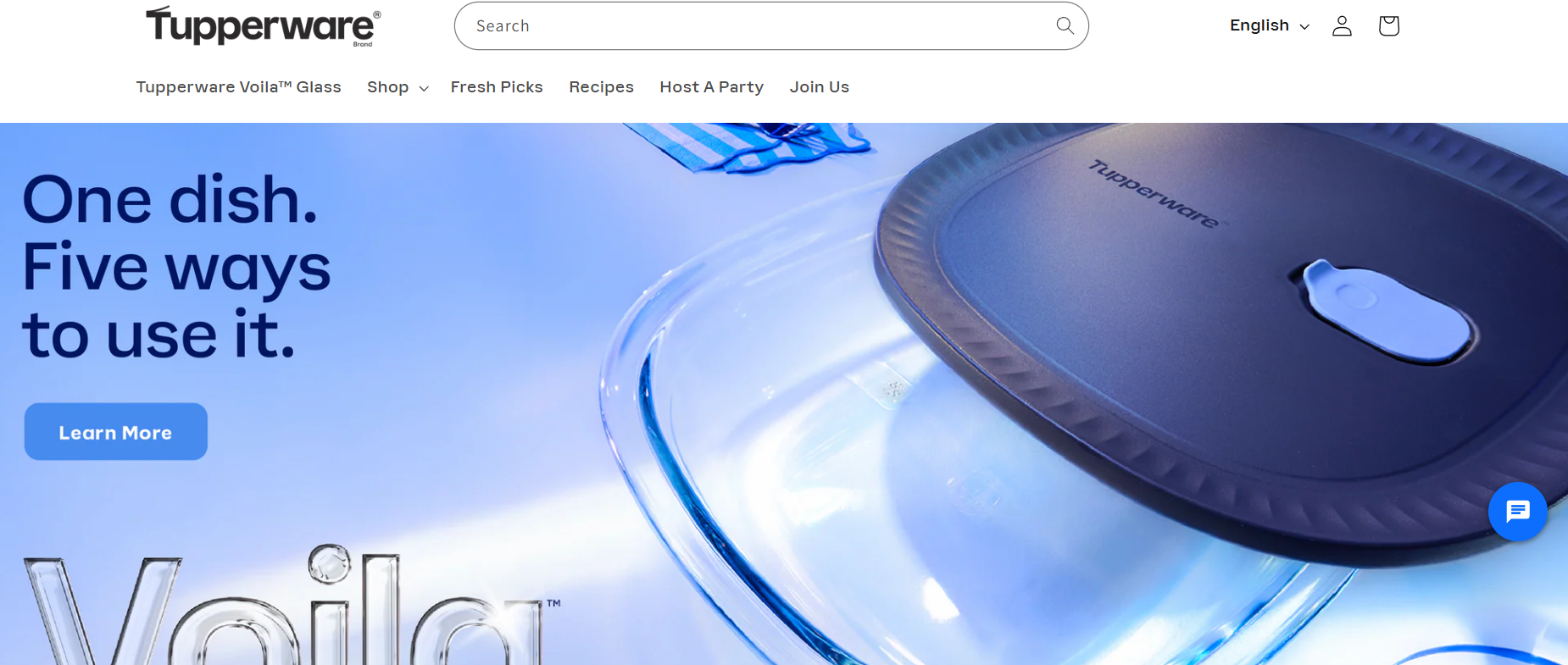

Tupperware: Pioneer of Food Storage Innovation

Tupperware represents the pioneering force in polypropylene container development, establishing the global standard for food storage solutions through continuous innovation, premium quality materials, and comprehensive product systems that address diverse consumer needs across international markets. Whether it’s a Thanksgiving feast or tomorrow’s lunch, Tupperware has the Food Storage Container for you! Made with high-quality materials and featuring air-tight seals, Tupperware’s food storage solutions keep food fresh, lock in flavor, and prevent spills.

Manufacturing capabilities encompass advanced polypropylene processing technologies that achieve exceptional dimensional accuracy, superior sealing performance, and innovative design features that enhance user experience while maintaining the durability and reliability that characterizes the Tupperware brand. Everything we make is built to last. Thanks to our proprietary designs, our dependability and durability are unbeatable. And our iconic style is timeless, so you’ve got tools you’ll love and trust for years to come.

Technical innovation includes specialized polypropylene formulations developed specifically for food storage applications, incorporating advanced additives that enhance material properties while maintaining food safety compliance and environmental responsibility. Made from high-quality polypropylene, our containers stand out for their durability and safety. This material is known for its strength and longevity, ensuring your containers maintain their integrity even with intensive use.

Product development excellence encompasses comprehensive container systems that integrate multiple sizes, specialized configurations, and innovative sealing technologies that optimize food preservation while providing convenient storage solutions for diverse household and commercial applications. Organize your kitchen like a pro with Tupperware storage containers. Synonymous with quality and style, our food storage containers are crafted from high-quality materials and are extremely safe to use. You can easily store dry goods, fresh produce, leftovers and more, ensuring optimal storage for better use.

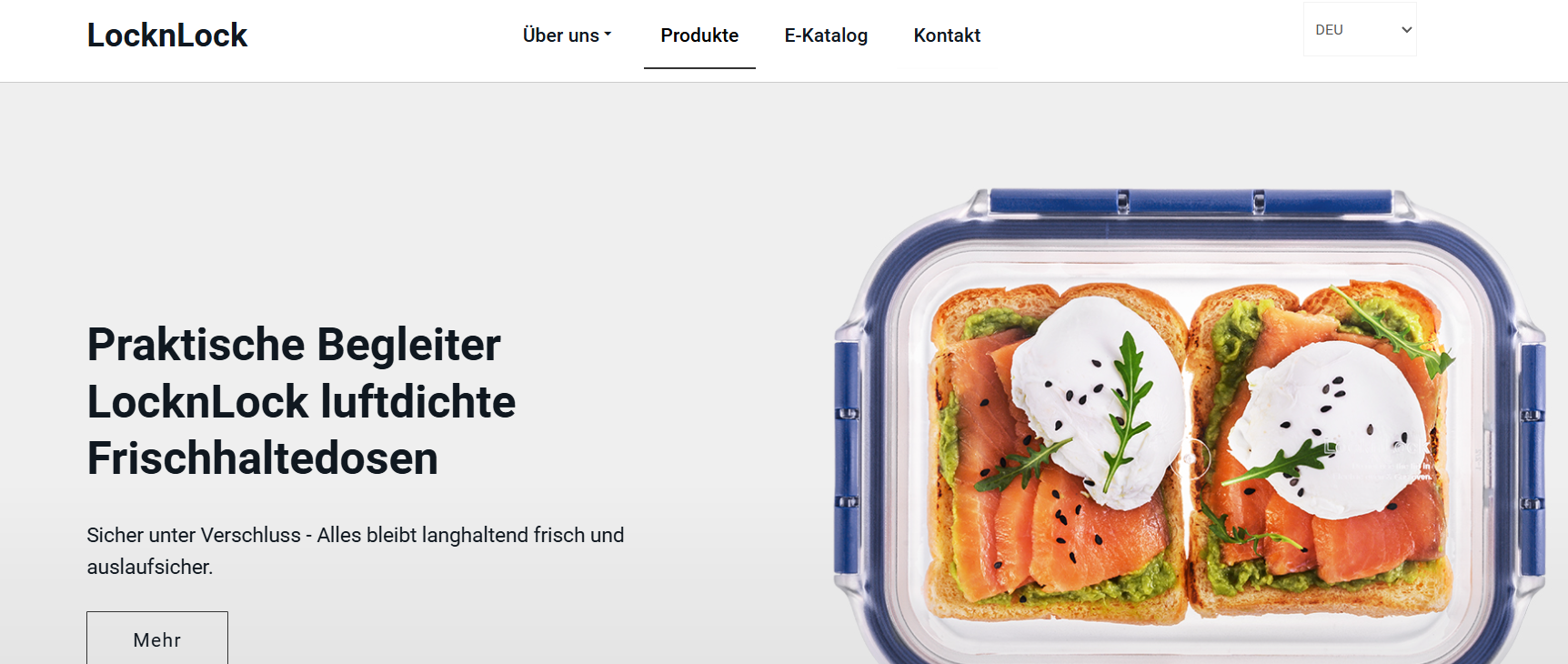

Lock & Lock: Korean Engineering Excellence

Lock & Lock has established itself as a global leader in polypropylene container manufacturing through innovative engineering, precision manufacturing, and comprehensive quality systems that deliver exceptional performance across food storage, organization, and commercial applications. Hollow silicone packing and four-side locking on the lid delivers outstanding airtightness. Strong durability allows the lid to open more than three million times.

Manufacturing innovation encompasses advanced injection molding technologies and precision tooling that achieve exceptional dimensional accuracy while maintaining consistent quality across high-volume production requirements. Unique 4-hinge locking system is durability tested for long-lasting performance up to 3 million uses. NO MESS, STAYS FRESH: Enhanced silicone seal is 100 percent airtight to keep foods fresh longer and 100 percent leakproof to prevent unwanted drips and spills.

Technical excellence focuses on polypropylene material optimization that enhances impact resistance, thermal stability, and chemical compatibility while maintaining the optical clarity and aesthetic appeal essential for premium food storage applications. BPA-FREE: Peace of mind for healthy, happy food storage. VERSATILE: Provides a convenient, all-in-one storage solution for the refrigerator, freezer, and pantry.

Quality control systems integrate comprehensive testing protocols that validate sealing performance, durability characteristics, and food safety compliance while ensuring manufacturing consistency that supports the company’s reputation for reliability and performance excellence. LocknLock’s unique 4-hinge locking system has been durability tested to last up to 3 million uses, and the enhanced silicone seal is 100% airtight to keep foods fresh longer and 100% leakproof to prevent messy drips and sloppy spills. BPA-free construction provides a healthy, versatile, and convenient storage solution for the refrigerator, freezer, pantry, or anywhere your foods need to stay fresh and organized.

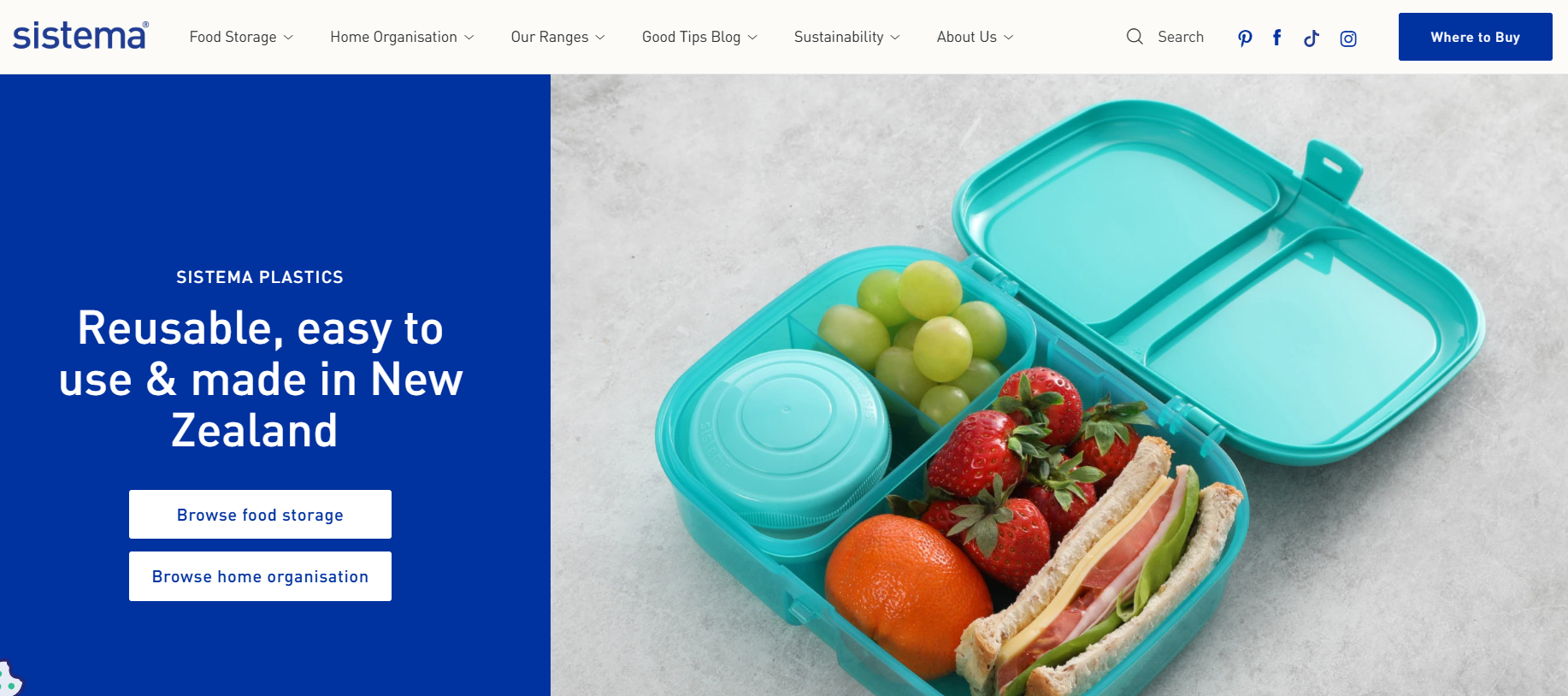

Sistema: New Zealand Innovation and Design

Sistema has achieved global recognition as an innovative polypropylene container manufacturer through emphasis on design excellence, functional innovation, and comprehensive product systems that address diverse storage and organization requirements across consumer and commercial markets. The Sistema KLIP IT Accents range is versatile, durable and hard wearing, with solutions to solve all your food storage needs. Featuring easy to use locking clips plus flexible seal, food stays fresher for longer.

Design innovation encompasses modular container systems that optimize space utilization while providing flexible configuration options that address diverse storage requirements. The modular stacking shapes ensures the most efficient use of space in the fridge, freezer and pantry. It is ideal for organising today’s busy kitchen and provides one of the worlds most comprehensive food storage solutions.

Manufacturing capabilities feature advanced polypropylene processing technologies that achieve exceptional material properties including enhanced flexibility, superior impact resistance, and optimal thermal performance while maintaining cost competitiveness essential for global market success. Designed and made in New Zealand. Phthalate free and BPA free.

Technical specialization includes development of polypropylene formulations optimized for specific applications, incorporating specialized additives that enhance performance characteristics while maintaining environmental responsibility and food safety compliance. Sistema distinctive, easy-to-use locking clips and flexible seals ensure food stays fresher for longer. This product is stackable and safe to use in the dishwasher (on the top rack), The microwave (without the lid), or in the fridge and freezer.

Altium Packaging: American Manufacturing Innovation

Altium Packaging represents innovation excellence in polypropylene container manufacturing through advanced processing technologies, comprehensive design capabilities, and integrated supply chain management that delivers high-performance packaging solutions for diverse industrial and consumer applications. We are committed to bringing our customers big design ideas and manufacturing excellence rooted in creative innovation and branding know-how. Request a quote Whether you call them jugs, bottles, rounds, or containers, Altium Packaging is a leading producer of standard and lightweight

Manufacturing excellence encompasses state-of-the-art processing facilities featuring advanced injection molding and thermoforming equipment that achieves exceptional precision while maintaining production efficiency essential for serving diverse market segments. The success of your products and the future of your organization drive us to excel in our effort to be among the leading plastic containers packaging suppliers in the world. Strong partnerships with those we serve are what matters most to the Altium Packaging team.

Innovation capabilities include comprehensive product development services that combine advanced material science with customer-focused design to create polypropylene containers that optimize performance while supporting brand differentiation and marketing objectives. The leading customer-centric packaging solutions provider that helps elevate your brand. From the talented designers of Studio PKG™, to our experienced manufacturing teams across the network, to our focus on environmental stewardship, Altium delivers.

Technical expertise encompasses specialized polypropylene formulations that address specific application requirements including enhanced barrier properties, improved thermal stability, and optimized mechanical characteristics while maintaining food safety compliance and environmental responsibility essential for modern packaging applications.

Polyethylene Containers Inc.: Specialized Manufacturing Excellence

Polyethylene Containers Inc. has established specialized expertise in rigid polypropylene container manufacturing through strategic focus on industrial and commercial applications that require exceptional durability, chemical resistance, and reliable performance under demanding operational conditions. Polyethylene Containers, Inc. founded in 1980, is a leading manufacturer of plastic pails & drums servicing our customers throughout the North America. We are dedicated to exceeding our customers’ expectations and fulfilling their packaging needs.

Manufacturing capabilities encompass advanced processing technologies including injection molding and thermoforming that achieve exceptional material properties while maintaining cost competitiveness essential for industrial applications requiring high-volume production and consistent quality standards. Trust in our customers & suppliers has been our key to success for over 30 years. Our record of Quality, Service, & Value to our customers is a legacy we are proud to continue.

Key Advantages of Leading Polypropylene Container Manufacturers:

-

Material Safety Excellence: FDA-approved, BPA-free formulations ensuring food contact safety

-

Thermal Performance: Superior temperature resistance from freezer to microwave applications

-

Chemical Resistance: Exceptional durability against cleaning chemicals and food acids

-

Mechanical Strength: Outstanding impact resistance and structural integrity

-

Manufacturing Precision: Advanced processing technologies ensuring consistent quality

-

Design Innovation: Comprehensive product development and customization capabilities

-

Environmental Responsibility: Sustainable manufacturing practices and recyclable materials

Innovation leadership focuses on sustainable polypropylene technology including post-consumer recycled content integration and energy-efficient manufacturing processes that reduce environmental impact while maintaining superior performance characteristics. Industry analysts predict a substantial growth in the PCR plastics market, with a projected annual growth rate of 8.3% through 2025 (Global PCR Plastics Market Report, 2023). This surge is attributed to increasing environmental regulations and a shift towards sustainable materials in various industries. At PCI, we’re right at the heart of this change.

Quality assurance systems encompass comprehensive testing protocols that validate mechanical properties, chemical resistance, and dimensional accuracy while ensuring compliance with industry standards and customer specifications essential for successful application in demanding industrial environments.

Inline Plastics: Food Service Innovation Leader

Inline Plastics has achieved recognition as an innovative leader in polypropylene container manufacturing for food service applications through development of advanced packaging solutions that combine exceptional performance with environmental responsibility and operational efficiency. From environmental sustainability to industry-disrupting innovations, Inline Plastics leads where others follow. For over fifty years, our revolutionary ideas have transformed the food packaging marketplace.

Manufacturing excellence encompasses specialized thermoforming technologies that produce complex polypropylene container configurations including tamper-evident features, integrated functionality, and optimized designs that enhance food safety while maintaining cost competitiveness. First tamper evident, tamper resistant, all-clear, polypropylene packaging product family for hot food applications. A growing portfolio, including vented options with anti-fog.

Innovation capabilities include comprehensive automation solutions that integrate container manufacturing with packaging operations, providing complete systems that optimize efficiency while maintaining quality standards essential for high-volume food service applications. Only thermoformed container manufacturer in the industry providing in-house packaging automation solutions Over 30 years of experience Improve efficiencies and decrease labor costs

Technical specialization encompasses development of polypropylene materials optimized for food service requirements including enhanced barrier properties, improved thermal performance, and specialized surface treatments that address specific operational challenges while maintaining food safety compliance and environmental responsibility throughout the complete product lifecycle.

Conclusion: Excellence Through Innovation and Quality

The seven leading polypropylene container manufacturers represent the convergence of material science excellence, manufacturing innovation, and customer focus that defines successful packaging solutions in dynamic global markets. These companies continue advancing polypropylene technology while maintaining quality standards and service excellence that support customer success across diverse applications and market segments.

Their collective leadership drives continuous advancement in sustainable materials, manufacturing processes, and application development that benefits industries worldwide while supporting broader environmental objectives and circular economy principles. Through continued investment in research and development, manufacturing capabilities, and customer service excellence, these manufacturers ensure continued market leadership while contributing to more effective and environmentally responsible packaging solutions.

Success in polypropylene container manufacturing requires comprehensive capabilities in material science, processing technology, quality management, and customer collaboration that create competitive advantages while supporting long-term sustainability objectives essential for continued industry growth and market leadership in an increasingly competitive global marketplace.