The global shift toward sustainable food packaging has accelerated dramatically in 2025, driven by consumer awareness, regulatory pressures, and corporate sustainability commitments that demand environmentally responsible alternatives to conventional plastic materials. The sustainable packaging market is expected to reach USD 315.16 billion in 2025 and grow at a 7.67% CAGR, reaching USD 456.04 billion by 2030, reflecting unprecedented industry transformation toward materials that balance performance requirements with environmental stewardship and circular economy principles.

Defining Sustainability in Plastic Food Packaging

Sustainable plastic food packaging encompasses materials and design approaches that minimize environmental impact throughout the complete product lifecycle while maintaining essential food safety, quality preservation, and performance characteristics required for effective food distribution systems. Sustainable materials meet our needs today without depleting natural resources or compromising future generations’ ability to meet their own needs, requiring comprehensive evaluation of resource consumption, manufacturing processes, use phase performance, and end-of-life management options.

Sustainability assessment criteria include renewable resource utilization, recyclability potential, biodegradability characteristics, carbon footprint minimization, and circular economy compatibility that enable materials to contribute positively to environmental objectives while fulfilling essential packaging functions. Modern sustainability frameworks evaluate multiple impact categories including climate change, resource depletion, ecosystem toxicity, and waste generation to provide comprehensive understanding of environmental performance across diverse material options and application scenarios.

The evolution toward sustainable packaging reflects fundamental shifts in consumer preferences, with 43% of consumers considering environmental impact a key factor when choosing products, creating market demands that drive innovation in bio-based materials, recycled content integration, and design optimization strategies that reduce material consumption while maintaining packaging effectiveness and food safety standards.

Bio-Based Plastic Materials Leading Innovation

Bio-based plastics represent the most significant advancement in sustainable food packaging, utilizing renewable feedstocks including corn starch, sugarcane, cassava, and other agricultural resources to create polymers that reduce dependence on fossil fuels while providing comparable performance characteristics to conventional plastics. These materials demonstrate superior sustainability profiles through renewable resource utilization, reduced carbon footprints, and enhanced end-of-life options including industrial composting and biodegradation under appropriate conditions.

Polylactic Acid (PLA) stands as the leading bio-based plastic for food packaging applications, derived primarily from corn starch and other plant-based feedstocks through fermentation processes that convert natural sugars into lactic acid monomers. PLA offers excellent clarity, good mechanical properties, and processing characteristics that enable conventional manufacturing while providing compostability under industrial conditions that reach temperatures of 60°C and maintain controlled humidity levels for appropriate degradation timeframes.

Performance characteristics of PLA include good optical clarity that showcases food products effectively, adequate barrier properties for many food applications, and thermal stability sufficient for cold and ambient temperature storage. However, limitations include lower heat resistance compared to conventional plastics, moisture sensitivity that requires consideration in humid environments, and composting requirements that necessitate access to industrial composting facilities for proper end-of-life management.

Polyhydroxyalkanoates (PHAs) represent an emerging class of bio-based plastics produced through bacterial fermentation of organic materials, offering superior biodegradability characteristics that enable degradation in marine environments, soil conditions, and home composting systems. PHAs demonstrate excellent barrier properties, thermal stability, and mechanical performance that enable applications requiring extended shelf life or demanding performance requirements while maintaining complete biodegradability under diverse environmental conditions.

Recycled Content Integration and Circular Economy

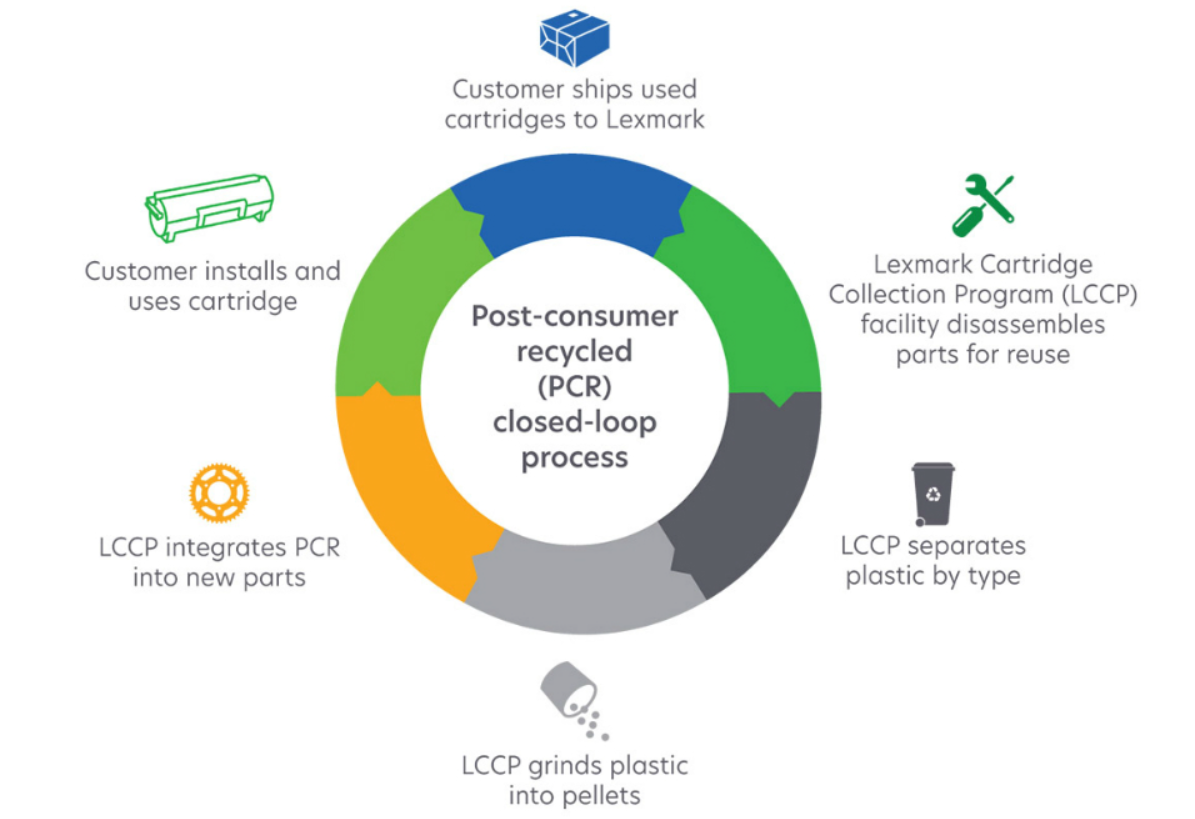

Post-consumer recycled (PCR) plastics constitute essential components of sustainable packaging strategies, diverting waste materials from landfills and incineration while reducing demand for virgin plastic production that consumes fossil fuel resources and generates greenhouse gas emissions. Advanced recycling technologies enable safe integration of recycled content into food packaging applications while maintaining food safety standards and performance characteristics essential for product protection and consumer confidence.

Mechanical recycling processes collect, clean, and reprocess post-consumer plastic containers into new packaging materials through washing, shredding, melting, and reforming operations that maintain polymer integrity while removing contaminants and additives that could compromise food safety. Advanced sorting technologies including near-infrared spectroscopy and artificial intelligence enable precise material separation that improves recycled material quality while reducing contamination risks that could affect final product performance.

Chemical recycling technologies represent breakthrough approaches that depolymerize waste plastics into molecular components that can be repolymerized into virgin-quality materials suitable for food contact applications. These processes break down plastic waste to its chemical building blocks, enabling complete purification and regeneration that produces materials indistinguishable from virgin plastics while utilizing waste feedstocks and supporting circular economy principles.

Quality assurance for recycled content materials requires comprehensive testing protocols including contaminant analysis, migration testing, and performance validation that ensures food safety compliance while verifying mechanical and barrier properties essential for packaging effectiveness. Regulatory frameworks continue evolving to support increased recycled content utilization while maintaining stringent safety standards that protect consumer health and confidence in recycled packaging materials.

Advanced Biodegradable and Compostable Solutions

Biodegradable plastic materials offer end-of-life advantages through natural decomposition processes that return materials to the environment without persistent pollution or microplastic accumulation that characterizes conventional plastic waste. Modern biodegradable plastics utilize advanced polymer chemistry to achieve controlled degradation rates, complete mineralization, and compatibility with existing waste management infrastructure while maintaining performance characteristics required for food packaging applications.

Compostable plastics meet rigorous standards including ASTM D6400 in the United States and EN 13432 in Europe that verify complete biodegradation within specified timeframes under controlled composting conditions. These materials demonstrate fragmentation within 12 weeks, biodegradation exceeding 90% within 180 days, and absence of toxic residues that could compromise compost quality or soil health following decomposition processes.

Starch-based biodegradable plastics combine renewable starch polymers with biodegradable additives to create materials that offer good mechanical properties, processing characteristics, and complete biodegradability under composting conditions. These materials utilize agricultural byproducts including potato starch, corn starch, and wheat starch to create packaging solutions that support agricultural economies while providing sustainable alternatives to conventional plastic materials.

Marine biodegradable plastics address growing concerns about ocean plastic pollution through materials designed to degrade safely in marine environments without contributing to microplastic accumulation or ecosystem disruption. These specialized materials undergo rigorous testing to verify biodegradation in seawater conditions while ensuring decomposition products do not negatively impact marine organisms or food chains.

High-Performance Recycled PET Solutions

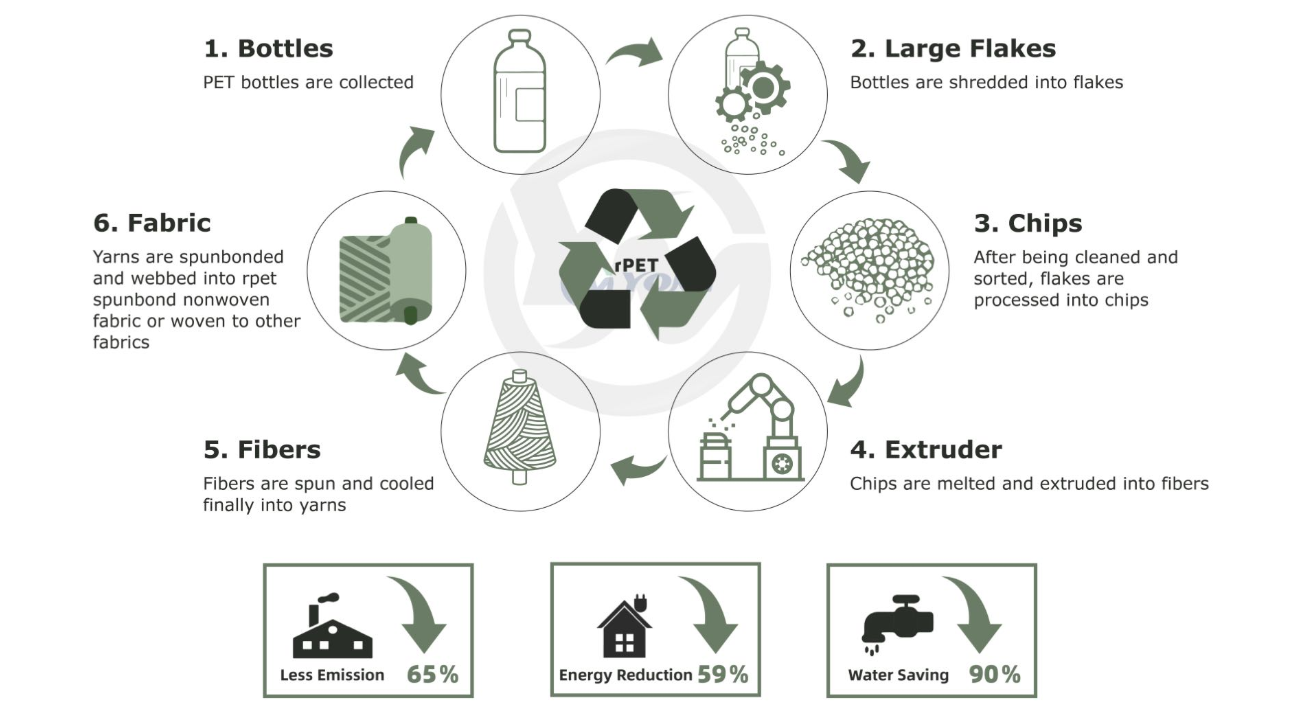

Recycled Polyethylene Terephthalate (rPET) represents the most successful example of circular economy implementation in food packaging, with established collection, processing, and manufacturing infrastructure that enables closed-loop recycling where post-consumer bottles become new food packaging materials. Advanced purification technologies including solid-state polymerization enable production of food-grade rPET that meets stringent safety standards while providing performance characteristics comparable to virgin materials.

Bottle-to-bottle recycling systems demonstrate exceptional sustainability performance through material recovery rates exceeding 90% and energy savings of 60% compared to virgin PET production. These systems utilize advanced washing technologies, contaminant removal processes, and polymer regeneration techniques that restore molecular weight and performance characteristics while maintaining food safety compliance and optical clarity essential for beverage and food packaging applications.

Enhanced barrier rPET incorporates specialized additives or multilayer constructions that improve oxygen and carbon dioxide barrier properties for applications requiring extended shelf life protection. These advanced materials enable sustainable packaging solutions for sensitive products including carbonated beverages, fruit juices, and ready-to-eat meals that demand superior protection characteristics while maintaining recycling compatibility and circular economy benefits.

Quality validation for rPET includes comprehensive testing protocols that verify chemical composition, barrier properties, mechanical performance, and food safety compliance through migration testing and analytical characterization. Regulatory approvals from FDA, European Food Safety Authority, and other international agencies provide confidence in rPET safety while supporting increased utilization in food packaging applications across global markets.

Polyolefin Recycling and Circular Solutions

Polyolefin materials including polyethylene and polypropylene represent significant opportunities for sustainable packaging through advanced recycling technologies, design optimization, and circular economy implementation that addresses the largest volume plastic categories in food packaging applications. Modern sustainable packaging materials generate fewer carbon emissions and often require less energy to produce, reducing overall carbon footprints while providing essential performance characteristics for food protection and distribution.

Advanced recycling technologies for polyolefins include pyrolysis processes that break down waste plastics into hydrocarbon feedstocks suitable for new polymer production, enabling chemical recycling that produces virgin-quality materials from waste streams. These technologies address contaminated waste streams that cannot be processed through mechanical recycling while supporting circular economy principles and reducing dependence on fossil fuel feedstocks.

Design for recyclability initiatives optimize polyolefin packaging through material selection, adhesive compatibility, and labeling systems that facilitate efficient collection and processing through existing recycling infrastructure. Mono-material designs eliminate incompatible material combinations while enhanced sorting technologies improve collection efficiency and material quality throughout the recycling process.

Ocean plastic recovery programs collect marine plastic waste for processing into new packaging materials, addressing environmental pollution while creating valuable feedstocks for sustainable packaging production. These initiatives demonstrate positive environmental impact through waste cleanup while producing materials that communicate strong sustainability messaging and environmental stewardship to consumers and stakeholders.

Key Sustainable Plastic Material Categories:

-

Bio-Based Plastics: PLA, PHA, starch-based materials derived from renewable resources

-

Recycled Content Materials: PCR PET, recycled polyolefins with verified circular content

-

Biodegradable Solutions: Compostable materials meeting international biodegradation standards

-

Advanced Composites: Bioplastic blends with natural fiber reinforcement and enhanced properties

-

Chemical Recycling Outputs: Virgin-quality materials from waste stream depolymerization

-

Marine Plastic Recovery: Ocean waste converted into new packaging applications

Regulatory Framework and Certification Standards

Regulatory compliance for sustainable plastic food packaging requires navigation of complex frameworks that address food safety, environmental claims, and end-of-life management across multiple jurisdictions. Certification programs including ASTM standards for compostability, FDA guidelines for recycled content, and European regulations for bio-based materials provide verification frameworks that ensure sustainable materials meet performance and safety requirements while supporting legitimate environmental claims.

Food contact approvals for sustainable materials require comprehensive testing including migration studies, toxicological assessment, and long-term stability evaluation that validates safety under intended use conditions. These requirements ensure sustainable alternatives maintain food safety standards while providing environmental benefits, requiring extensive documentation and ongoing monitoring that supports consumer confidence and regulatory compliance.

Environmental certification programs including Cradle to Cradle, USDA BioPreferred, and European Ecolabel provide third-party verification of sustainability claims while establishing credible standards for environmental performance assessment. These programs evaluate multiple impact categories including material health, renewable energy use, water stewardship, and social fairness that provide comprehensive sustainability assessment frameworks.

Supply chain verification ensures sustainable material claims through traceability systems, audit programs, and documentation requirements that validate renewable content, recycled content percentages, and processing methods throughout the manufacturing supply chain. These systems support authentic sustainability claims while preventing greenwashing and ensuring consumer trust in sustainable packaging alternatives.

Economic Considerations and Market Adoption

Economic viability of sustainable plastic food packaging continues improving through technology advancement, scale development, and cost optimization that reduces price premiums while improving performance characteristics and availability. Market forces including consumer demand, regulatory requirements, and corporate sustainability commitments drive investment in sustainable alternatives that support continued cost reduction and performance improvement.

Total cost of ownership analysis encompasses material costs, processing efficiency, performance benefits, and end-of-life value that provide comprehensive economic assessment beyond initial material pricing. Sustainable materials may offer advantages through improved processing characteristics, enhanced marketing value, regulatory compliance benefits, and waste management cost reduction that offset higher material costs while providing overall economic benefits.

Investment in sustainable packaging infrastructure includes recycling facility expansion, bio-based production capacity, and technology development that supports continued market growth and cost reduction. Government incentives, corporate commitments, and consumer demand drive capital investment that improves technology maturity and economic competitiveness of sustainable alternatives.

Market adoption strategies require collaboration between material suppliers, packaging converters, food manufacturers, and retailers to develop integrated solutions that address performance requirements while achieving sustainability objectives and economic targets. Successful implementation requires stakeholder alignment, consumer education, and infrastructure development that supports widespread adoption and market transformation.

Conclusion: The Future of Sustainable Food Packaging

Sustainable plastic food packaging materials represent a fundamental transformation in packaging industry practices, driven by environmental necessity, consumer demand, and technological advancement that enables high-performance alternatives to conventional materials. The convergence of bio-based materials, recycled content integration, and circular economy principles creates unprecedented opportunities for packaging solutions that protect food while supporting environmental stewardship and resource conservation objectives.

Continued innovation in sustainable materials focuses on performance enhancement, cost optimization, and infrastructure development that accelerates market adoption while addressing remaining technical challenges and economic barriers. The industry trajectory toward sustainability reflects permanent structural changes that prioritize environmental responsibility alongside traditional performance criteria, ensuring sustainable materials become standard practice rather than premium alternatives.

Success in sustainable packaging requires comprehensive approach that considers material selection, design optimization, supply chain integration, and end-of-life management throughout the complete product lifecycle. This holistic perspective enables development of packaging solutions that deliver superior environmental performance while maintaining food safety, quality preservation, and economic viability essential for successful market implementation and long-term sustainability transformation.

For specific sustainable material recommendations and implementation strategies, consult with packaging specialists and material suppliers who can provide detailed guidance based on your unique product requirements and sustainability objectives.