The selection of optimal plastic materials for takeout containers represents a critical decision that impacts food safety, thermal performance, structural integrity, and customer satisfaction throughout the delivery process. Modern delivery services demand packaging solutions that maintain food quality during transport while providing cost-effectiveness, durability, and environmental responsibility that addresses both operational requirements and consumer expectations for safe, convenient food delivery experiences.

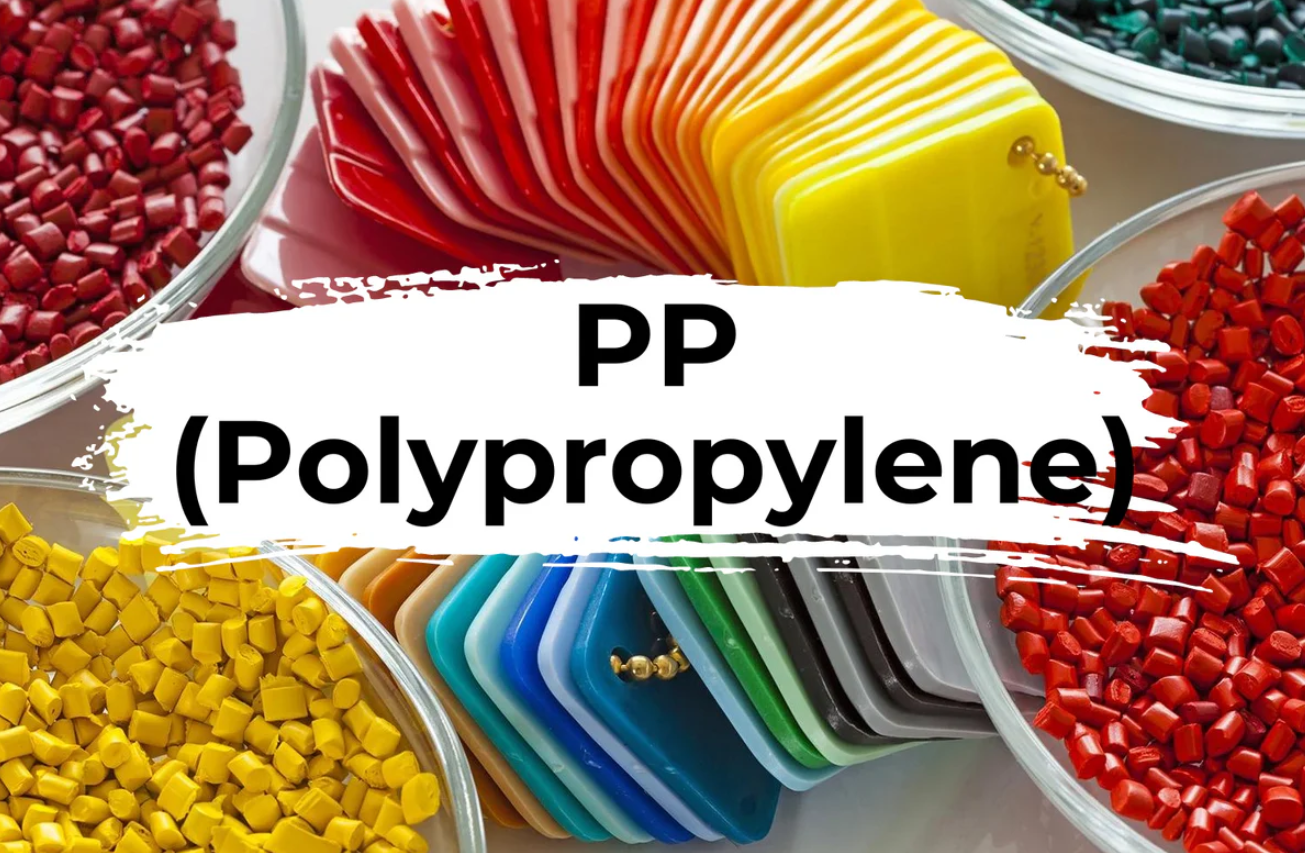

Polypropylene (PP): The Gold Standard for Delivery Containers

Polypropylene stands as the premier material choice for plastic takeout containers used in delivery applications due to its exceptional combination of thermal stability, chemical resistance, and food safety characteristics that address the demanding requirements of modern food delivery operations. This versatile thermoplastic provides superior performance across temperature ranges from freezer storage through microwave heating, making it ideal for containers that must accommodate diverse food types and heating requirements.

The molecular structure of polypropylene creates exceptional chemical resistance that prevents interaction with acidic foods, oils, and cleaning chemicals commonly encountered in food service applications. This chemical inertness ensures food flavor integrity while preventing container degradation that could compromise structural performance or food safety during extended delivery periods and temperature fluctuations.

Thermal performance represents a defining advantage of polypropylene containers, with exceptional heat resistance enabling direct microwave heating without deformation, melting, or chemical migration. The material maintains dimensional stability and mechanical properties across temperature ranges from -40°C to 140°C, supporting applications requiring hot food transport, refrigerated storage, and consumer reheating without performance degradation.

Food safety compliance includes FDA approval for direct food contact applications alongside BPA-free composition that addresses growing consumer health concerns. Polypropylene’s inherent safety characteristics eliminate risks associated with chemical leaching while providing reassurance to health-conscious consumers increasingly scrutinizing packaging materials used for food delivery applications.

Manufacturing advantages include excellent processability through injection molding and thermoforming techniques that enable complex container geometries, precision dimensional control, and cost-effective high-volume production. The material’s favorable processing characteristics support innovative design features including stackable configurations, integrated compartments, and secure closure systems that optimize delivery efficiency while maintaining food presentation quality.

Polystyrene (PS): Lightweight Economy Solutions

Polystyrene provides cost-effective solutions for plastic takeout containers where weight minimization and economic efficiency represent primary considerations, particularly for applications involving room temperature or cold food delivery requiring basic protection and containment. The material’s low density creates lightweight containers that reduce shipping costs while maintaining adequate structural performance for less demanding delivery applications.

Crystal polystyrene offers excellent clarity and aesthetic appeal that enhances food presentation while providing rigid structural characteristics suitable for dry goods, baked items, and cold food applications. The material’s optical properties enable attractive product visibility that supports marketing objectives while maintaining cost competitiveness essential for high-volume delivery operations with tight margin requirements.

Processing characteristics include excellent moldability and dimensional stability that enable precision manufacturing of complex geometries and detailed features. Polystyrene’s favorable flow properties during molding create smooth surface finishes and sharp detail reproduction that enhance container aesthetics while maintaining manufacturing efficiency and cost control essential for competitive market positioning.

Limitations include relatively low heat resistance that restricts applications to room temperature and cold food delivery, preventing use in applications requiring hot food transport or microwave heating. The material’s brittleness under impact conditions requires careful handling during packaging and delivery operations while temperature restrictions limit versatility compared to higher-performance alternatives.

Environmental considerations include recyclability through established collection systems alongside ongoing development of enhanced recycling technologies that improve material recovery and reprocessing efficiency. However, growing regulatory restrictions and consumer preferences for sustainable alternatives are driving market evolution toward more environmentally responsible material options.

Polyethylene Terephthalate (PET): Clarity and Performance Excellence

Polyethylene terephthalate delivers exceptional optical clarity combined with robust mechanical properties that make it ideal for delivery containers requiring product visibility, structural integrity, and moderate temperature resistance. The material’s crystal-clear appearance provides superior food presentation capabilities while maintaining lightweight characteristics that optimize delivery efficiency and reduce transportation costs.

Barrier properties represent a significant advantage of PET containers, providing excellent resistance to oxygen, moisture, and volatile compounds that preserve food freshness during extended delivery periods. These barrier characteristics extend food shelf life while preventing flavor migration and contamination that could compromise food quality and customer satisfaction in delivery applications.

Structural performance includes excellent impact resistance and dimensional stability that ensure containers maintain integrity during handling, transport, and storage operations typical of food delivery systems. PET’s toughness characteristics prevent cracking and breaking while maintaining clear appearance and functional performance throughout demanding delivery applications.

Temperature capabilities enable applications requiring moderate heat resistance while maintaining structural integrity and optical clarity. Though not suitable for high-temperature applications like microwave heating, PET containers effectively handle warm foods and ambient temperature variations encountered during typical delivery operations.

Recyclability advantages include widespread acceptance in municipal recycling programs alongside established reprocessing infrastructure that supports circular economy principles. PET’s recyclability characteristics address environmental concerns while providing end-of-life value that supports sustainable packaging strategies increasingly demanded by environmentally conscious consumers.

High-Impact Polystyrene (HIPS): Enhanced Durability

High-Impact Polystyrene represents an enhanced version of standard polystyrene that incorporates rubber modifiers to improve toughness and impact resistance while maintaining cost competitiveness and processing advantages. This material provides superior durability compared to crystal polystyrene while retaining favorable economic characteristics that support high-volume delivery applications requiring enhanced structural performance.

Impact resistance improvements address the brittleness limitations of standard polystyrene through incorporation of elastomeric modifiers that absorb impact energy and prevent crack propagation. These enhancements enable more robust container designs that withstand handling stresses encountered during packaging, transport, and delivery operations while maintaining cost advantages over premium engineering plastics.

Processing characteristics retain the favorable moldability and dimensional control associated with polystyrene materials while providing enhanced structural performance. HIPS maintains excellent flow properties during injection molding and thermoforming while enabling production of more durable containers with improved resistance to mechanical damage and deformation.

Thermal limitations remain similar to standard polystyrene, restricting applications to room temperature and cold food delivery while preventing use in applications requiring hot food transport or consumer heating. These temperature constraints limit versatility but enable cost-effective solutions for specific delivery applications not requiring elevated temperature performance.

Application suitability includes delivery containers for baked goods, cold foods, and ambient temperature items where enhanced durability provides value while temperature limitations do not impact functionality. HIPS containers serve applications requiring better protection than standard polystyrene while maintaining economic advantages over higher-performance alternatives.

CPET (Crystallized Polyethylene Terephthalate): Premium Performance

Crystallized Polyethylene Terephthalate represents the premium option for plastic delivery containers requiring exceptional thermal performance, structural integrity, and versatility across demanding temperature applications. The crystallization process creates a high-performance material that maintains properties from freezer temperatures through conventional oven heating, providing unmatched versatility for diverse delivery applications.

Thermal performance excellence enables CPET containers to withstand temperatures from -40°C to 220°C while maintaining structural integrity and dimensional stability. This exceptional temperature range supports applications requiring freezer storage, hot food transport, and consumer reheating through conventional ovens and microwave applications, providing comprehensive versatility unmatched by other plastic materials.

Key Performance Characteristics of Premium Delivery Container Materials:

-

Thermal Stability: Temperature resistance from freezer through oven heating applications

-

Chemical Resistance: Inertness to acidic foods, oils, and cleaning chemicals preventing degradation

-

Structural Integrity: Impact resistance and dimensional stability throughout delivery operations

-

Food Safety: FDA approval and migration compliance ensuring safe food contact performance

-

Barrier Properties: Protection against oxygen, moisture, and contaminant penetration

-

Optical Clarity: Superior visibility for food presentation and marketing objectives

-

Processing Efficiency: Moldability enabling complex geometries and precision manufacturing

-

Environmental Responsibility: Recyclability and sustainable material options

Mechanical properties include exceptional impact resistance, structural rigidity, and dimensional stability that ensure containers maintain performance throughout demanding delivery applications. CPET’s crystalline structure provides superior strength characteristics that prevent deformation while maintaining lightweight properties essential for delivery efficiency and cost control.

Food safety compliance encompasses comprehensive FDA approval for food contact applications alongside superior barrier properties that prevent chemical migration while preserving food quality. CPET’s inert characteristics ensure food safety and flavor integrity throughout extended delivery periods and temperature cycling that characterizes modern food delivery operations.

Manufacturing precision enables complex container designs incorporating advanced features like compartmentalization, venting systems, and secure closure mechanisms that optimize functionality while maintaining aesthetic appeal. CPET’s processing characteristics support innovative design solutions that enhance delivery efficiency while improving customer experience and satisfaction.

Cost considerations reflect the premium pricing associated with CPET materials and processing requirements, making this option suitable for applications where superior performance justifies higher material costs. Premium delivery services and specialized applications requiring exceptional thermal performance find CPET containers provide competitive advantages that support value-based pricing strategies.

Material Selection Criteria for Delivery Applications

Optimal material selection requires comprehensive evaluation of performance requirements, cost considerations, and application constraints that characterize specific delivery operations and customer expectations. Temperature requirements represent the primary selection criteria, determining whether applications require basic ambient temperature performance or advanced thermal capabilities supporting hot food delivery and consumer heating options.

Food compatibility considerations include chemical resistance requirements, barrier property needs, and safety compliance standards that ensure materials provide appropriate protection while maintaining food quality throughout delivery operations. Acidic foods, oily products, and specialized items may require specific material characteristics that address potential interactions and preserve food integrity.

Structural requirements encompass impact resistance, dimensional stability, and closure performance that ensure containers maintain functionality throughout handling, transport, and storage operations typical of delivery systems. Container designs must withstand stacking loads, handling stresses, and environmental conditions while maintaining secure closure and aesthetic appeal.

Economic factors include material costs, processing expenses, and volume requirements that influence total packaging costs and competitive positioning. High-volume operations may justify investment in premium materials through improved performance and customer satisfaction, while cost-sensitive applications require optimization of performance characteristics against material expenses.

Environmental considerations increasingly influence material selection as consumers and regulatory frameworks prioritize sustainable packaging options. Recyclability, biodegradability, and environmental impact assessment guide material choices while balancing performance requirements with sustainability objectives and regulatory compliance needs.

Innovation Trends and Future Developments

Sustainable material development continues driving innovation in plastic takeout container materials through advancement of bio-based polymers, enhanced recyclability, and circular economy integration that addresses environmental concerns while maintaining performance characteristics. Plant-based alternatives including PLA (Polylactic Acid) and PHA (Polyhydroxyalkanoates) provide biodegradable options with improving performance characteristics suitable for delivery applications.

Smart packaging integration includes development of active and intelligent packaging systems that monitor food quality, temperature exposure, and contamination while providing consumers with information supporting food safety and quality assessment. These technologies enhance delivery container functionality while supporting premium positioning and customer value creation.

Advanced barrier technologies include development of enhanced protective characteristics through nano-coatings, multi-layer structures, and specialized additives that improve food preservation while maintaining material recyclability and environmental responsibility. These innovations extend food shelf life while reducing waste and supporting delivery efficiency optimization.

Processing technology advancement enables more efficient manufacturing, improved material utilization, and enhanced product performance through automation, precision control, and integrated quality management systems. These improvements support cost reduction while enhancing product consistency and performance characteristics essential for competitive market positioning.

Regulatory evolution continues influencing material selection through environmental standards, food safety requirements, and sustainability mandates that create both challenges and opportunities for material innovation and market development. Successful navigation of evolving regulatory frameworks requires proactive material development and comprehensive compliance strategies.

Conclusion: Optimizing Material Selection for Delivery Success

The selection of optimal plastic materials for takeout containers requires comprehensive evaluation of thermal requirements, food compatibility, structural performance, and cost considerations that characterize specific delivery applications and customer expectations. Polypropylene emerges as the preferred general-purpose solution providing excellent balance of performance, safety, and cost-effectiveness suitable for diverse delivery requirements.

Premium applications requiring exceptional thermal performance and versatility benefit from CPET materials despite higher costs, while cost-sensitive operations may find polystyrene and HIPS provide adequate performance for specific applications not requiring advanced thermal capabilities. PET offers superior clarity and barrier properties for applications where food presentation and preservation represent primary considerations.

Success in material selection requires understanding of specific application requirements, regulatory constraints, and customer expectations while balancing performance optimization against economic considerations and environmental responsibility. The evolution toward sustainable alternatives and smart packaging technologies creates opportunities for innovation while addressing growing market demands for environmental stewardship and enhanced functionality.