The United States has emerged as a significant hub for biodegradable takeout container manufacturing, driven by increasing environmental consciousness, stringent state regulations, and growing consumer demand for sustainable packaging solutions. As global awareness of plastic pollution and sustainability surges, the demand for biodegradable food containers has skyrocketed. From eco-conscious consumers to multinational food chains, the urgency to replace plastic with compostable, zero-waste, and plant-based alternatives has never been stronger. Businesses now seek not just packaging, but solutions that align with environmental values and local compliance standards.

The American Biodegradable Container Manufacturing Landscape

The US biodegradable takeout container industry has achieved remarkable growth through strategic investment in sustainable technologies, comprehensive regulatory compliance, and innovative material science that addresses the demanding requirements of American food service markets. By 2030, Pactiv Evergreen aims to manufacture 100 percent of its products using materials that are recycled, recyclable, or renewable. This commitment represents the broader industry transformation toward sustainability leadership.

American manufacturers leverage sophisticated supply chains, advanced processing technologies, and comprehensive quality management systems that ensure consistent performance while maintaining environmental responsibility. The integration of domestic raw material sourcing, local manufacturing capabilities, and established distribution networks creates competitive advantages that support both cost competitiveness and environmental stewardship throughout the product lifecycle.

Regulatory frameworks including state-level plastic reduction mandates, FDA food safety requirements, and composting certification standards drive continuous innovation while ensuring product safety and environmental authenticity. These regulatory drivers support market development while creating barriers to entry that benefit established manufacturers with proven compliance capabilities and sustainability credentials.

Sabert Corporation: Manufacturing Excellence and Innovation Leadership

Sabert Corporation stands as America’s premier biodegradable takeout container manufacturer, leveraging over 40 years of industry expertise and comprehensive manufacturing capabilities to serve diverse market segments across North America. We are a leading global manufacturer of innovative food packaging products and solutions with more than 30 years in the packaging and food service industry. Headquartered in Sayreville, New Jersey, we operate North American facilities in New Jersey, California, Illinois, Indiana, Kentucky and Texas as well as manufacturing facilities in Belgium, Poland, and China.

Manufacturing excellence encompasses comprehensive domestic production capabilities including advanced molded pulp processing, precision thermoforming, and innovative material science that enables creation of high-performance biodegradable containers. Sabert is a global leader in sustainable and innovative food packaging solutions with operations spanning the globe, including seven domestic manufacturing plants, one domestic recycling facility, two advanced development centers, and four international locations. This extensive infrastructure supports reliable supply chain performance while maintaining quality consistency across high-volume production requirements.

Innovation leadership focuses on sustainable material development and advanced biodegradable technologies. Sustainable packaging that performs, our Green Collection features more than 60 certified compostable items. Sabert manufactures both the bases and lids, ensuring optimal lid fit and leak resistance. The company’s comprehensive approach to biodegradable container development addresses specific application requirements while maintaining operational efficiency and cost competitiveness.

Sustainability commitment extends beyond product development to encompass manufacturing processes and supply chain management. Globally, our teams launched 333 products, of which 76% are categorized as sustainable through recyclability, compostability, and the use of recycled or renewable content. Sabert has in-house recycling capabilities through our plant, Nuvida, one of the world’s largest processors and suppliers of food-grade recycled plastic. This vertical integration enables comprehensive sustainability solutions while maintaining competitive manufacturing costs.

Quality assurance systems ensure comprehensive compliance with international food safety standards while supporting biodegradability certification requirements. All products using the company’s molded Pulp Plus™ and Pulp Ultra™ formulations, which are manufactured at the Greenville, Texas facility, have been awarded certification from the Biodegradable Products Institute (BPI) and meets ASTM standards for compostability, demonstrating commitment to authentic environmental performance.

Pactiv Evergreen: Large-Scale Sustainable Manufacturing

Pactiv Evergreen represents large-scale biodegradable container manufacturing capabilities through comprehensive production facilities, material expertise, and sustainability commitment that serves major North American food service markets. With a team of approximately 16,500 employees across more than 70 manufacturing facilities, Pactiv Evergreen is a leading manufacturer and distributor of fresh food and beverage packaging in North America.

Manufacturing scale enables significant production capacity while maintaining consistent quality and delivery performance essential for serving large-volume customers including national restaurant chains and institutional food service operations. The company operates 53 manufacturing plants, 26 warehouses, and 8 distribution centers. This extensive infrastructure supports reliable supply chain management while providing flexibility to accommodate diverse customer requirements and seasonal demand fluctuations.

Product development capabilities encompass comprehensive biodegradable solutions across multiple segments. The company’s Foodservice segment manufactures a broad range of products that enable consumers to eat and drink where they want and when they want with convenience, including food containers, drinkware (such as hot and cold cups and lids), tableware, serviceware, and other products that make eating on-the-go easier and more enjoyable.

Sustainability innovation represents a core strategic focus with ambitious environmental objectives. Sustainable innovation in particular is critical to Pactiv Evergreen, who today provides customers with sustainable alternatives across almost all products and categories. Indeed, the company has introduced thousands of innovative new products over the last five years, including resealable beverage cartons, strawless lids, compostable cutlery, and polyethylene terephthalate (PET) containers made with recycled content, reflecting Pactiv Evergreen’s commitment to sustainable lifecycle principles.

Advanced materials development includes specialized biodegradable formulations and innovative composites that address specific application requirements. Recently, the company also partnered with a key strategic customer to launch new circular cups made from post-consumer recycled polypropylene and bio-based materials, including the customer’s used cooking oil. This collaborative approach to innovation demonstrates commitment to circular economy principles while creating competitive differentiation.

World Centric: Specialized Compostable Solutions

World Centric has established itself as a specialized leader in compostable takeout containers through focused commitment to sustainable materials, environmental stewardship, and comprehensive certification standards that address the most demanding sustainability requirements. We manufacture compostable and reusable foodservice and packaging products and give 25% of our profits to social and environmental organizations to further their work in creating a better world.

Product specialization encompasses comprehensive compostable container solutions utilizing advanced sustainable materials. World Centric® take out containers are made from either sustainable unbleached plant fiber with no added PFAS, FSC® certified NoTree® paper, or bio-based plastic made from plant sugars. Meets ASTM standards for commercial composting where available. This material diversity enables addressing varied application requirements while maintaining authentic biodegradability and environmental responsibility.

Performance characteristics ensure biodegradable materials meet demanding functional requirements across temperature ranges and food types. Our line of rectangular and round clear deli containers are well-suited for cold and warm foods up to 120°F, while our bamboo and molded plant fiber containers and lids are perfect for both cold and hot foods. This thermal versatility supports diverse food service applications while maintaining structural integrity and user safety.

Environmental commitment extends beyond product characteristics to encompass comprehensive lifecycle management. In an active commercial compost, World Centric® products break down in 180 days. World Centric certified compostable products, including plates, cups, bowls, cutlery and containers are certified by the Biodegradable Products Institute (BPI), or other 3rd Party organizations. This means that they have been tested to break down into compost within 100 days.

Sustainability philosophy encompasses comprehensive environmental stewardship and social responsibility that differentiates World Centric from conventional packaging manufacturers. World Centric compostable to-go containers are made from natural and renewable materials such as sugarcane bagasse, wheat straw, and corn starch. These renewable materials help to pull carbon from the air and are regrown every year. World Centric products are compostable, so they can break down into the soil and help the crops to regrow. World Centric’s compostable to-go containers complete a zero-waste circle, reducing the amount of trash sent to landfills.

Karat Packaging (Lollicup USA): Comprehensive Biodegradable Portfolio

Karat Packaging, operating through Lollicup USA Inc., represents comprehensive biodegradable container manufacturing through diverse product portfolios, environmental specialization, and integrated supply chain capabilities that serve varied market segments across the United States. Karat Packaging Inc. is the holding company that primarily operates through its wholly owned subsidiary, Lollicup USA Inc., a specialty distributor and manufacturer of single-use disposable products used in a variety of restaurant and food service settings. Our products include food packaging, containers, tableware, cups, lids, cutlery and straws, and are available in plastic, paper, bagasse, biopolymer-based, and other compostable forms.

Product diversity encompasses comprehensive sustainable solutions through multiple brands and material platforms. Karat®, our flagship brand, provides an extensive selection of high-quality disposable products, including food packaging, containers, tableware, cups, lids, cutlery, and straws. Karat Earth® focuses on eco-friendly products, offering sustainable alternatives for environmentally-conscious customers. This brand differentiation enables addressing diverse customer requirements from conventional applications through specialized sustainability mandates.

Environmental specialization through the Karat Earth® brand demonstrates commitment to authentic biodegradable solutions. Karat Earth® is dedicated to environmental sustainability. We offer plant-based and compostable products, including cups, food containers, and utensils crafted from renewable resources. These products are not only sturdy and reliable, but also a powerful statement of your commitment to the environment.

Certification excellence ensures comprehensive compliance with biodegradability standards while supporting customer confidence in environmental claims. Our BPI-certified compostable products adhere to ESG governance, ensuring they break down safely. Biodegradable Products Institute® (BPI) certification program ensures that products and packaging displaying the BPI® logo have been independently tested and verified according to scientifically based standards.

Market positioning reflects established relationships with major food service customers across multiple segments. Karat® by Lollicup™ is a rapidly-growing manufacturer and distributor of environmentally friendly, single-use disposable products, primarily used in restaurants and foodservice settings. The company supplies a wide range of products for national restaurant chains, as well as smaller, regional chains.

Good Start Packaging: Small Business Focus and Customization

Good Start Packaging has developed specialized expertise serving small and medium-sized food service businesses through comprehensive biodegradable container solutions, flexible ordering systems, and customer-focused service that addresses the unique requirements of independent restaurants and regional chains. Good Start Packaging offers a variety of compostable to-go containers including fiber, paper, and PLA-based boxes. Their product line features specialized options such as burger boxes, pizza boxes, sushi boxes, and taco boxes to suit diverse food service needs.

Customer service excellence encompasses flexible ordering requirements and comprehensive application support that enables smaller businesses to access sustainable packaging solutions. Overview: A dedicated supplier of wholesale biodegradable food containers in the U.S., catering especially to small restaurants and food trucks. No MOQs for many items. Excellent U.S. warehousing and fast delivery. This market focus addresses the specific needs of businesses requiring smaller quantities and rapid turnaround times.

Material expertise encompasses diverse sustainable options that address varied application requirements and budget constraints. Compostable take out containers are plant-based packaging options, typically made from materials like fiber or PLA (polylactic acid). They provide an eco-friendly alternative to foam or plastic, helping your business reduce its environmental footprint while offering sturdy, high-quality containers for fresh food. These containers appeal to environmentally conscious consumers and can enhance your brand’s sustainability credentials.

Application specialization includes comprehensive solutions for specific food service segments and operational requirements. Take-out containers are ideal for foodservice businesses, from bakeries and restaurants to cafés, that need reliable and eco-friendly packaging for items like cakes, pastries, macarons, and other baked goods. Good Start Packaging’s to-go boxes, clamshells, and trays offer versatile, food-safe solutions suited for everyday use.

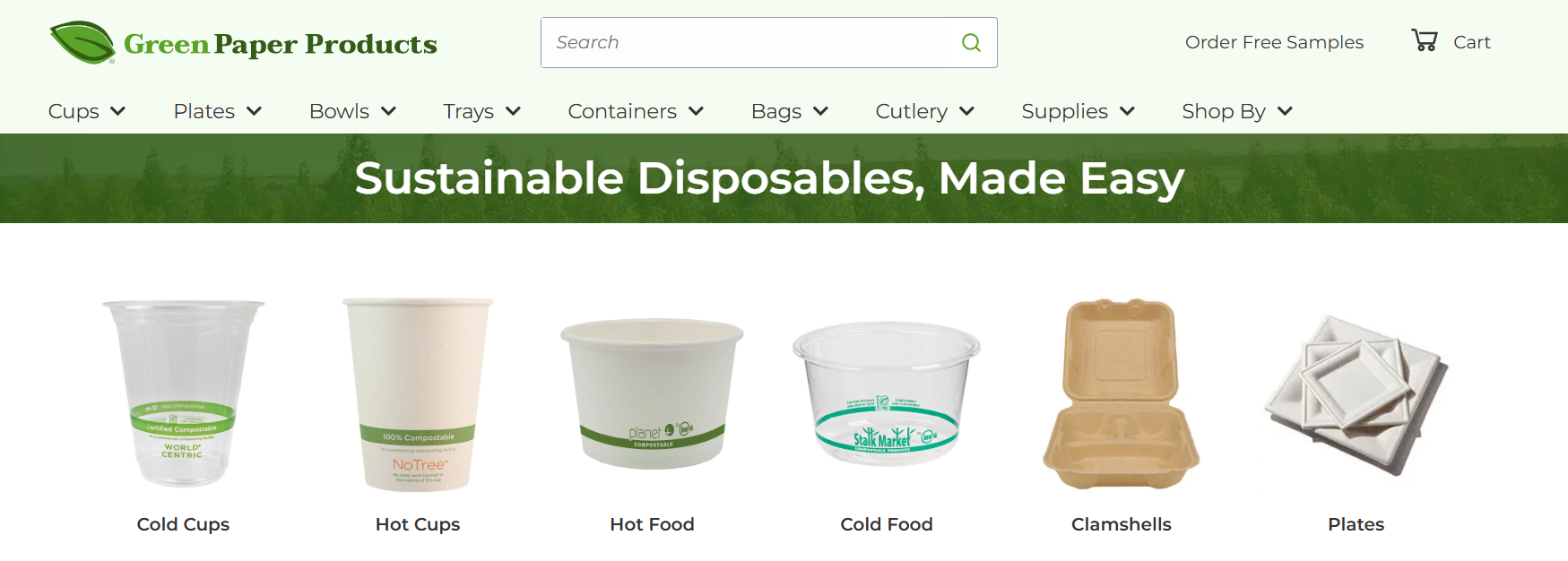

Green Paper Products: Distribution and Retail Excellence

Green Paper Products represents specialized distribution excellence in biodegradable takeout containers through comprehensive product curation, educational expertise, and retail service capabilities that serve businesses seeking reliable sustainable packaging solutions. Durable heavyweight food containers made from sugarcane, bamboo, or wheat straw are perfect for hot foods and carry-out meals. Clear PLA containers from corn resin are great for cold foods and salads. Durable and dependable, our food containers meet the demands of restaurants and food service businesses that are looking to eliminate single-use plastic and styrofoam.

Key Advantages of American Biodegradable Container Manufacturers:

-

Domestic Manufacturing: Comprehensive production facilities across multiple states ensuring supply chain reliability

-

Regulatory Compliance: Extensive experience with FDA, USDA, and state-level sustainability requirements

-

Certification Excellence: BPI, ASTM, and third-party biodegradability validation ensuring authentic environmental performance

-

Material Innovation: Advanced research and development in sustainable polymers and plant-based alternatives

-

Customer Service: Comprehensive technical support and application engineering for diverse food service requirements

-

Quality Assurance: Rigorous testing protocols ensuring food safety and performance consistency

-

Scalability: Production capabilities serving requirements from small restaurants through national chains

Product curation encompasses comprehensive biodegradable solutions from leading manufacturers while providing educational resources and technical support. World Centric NoTree food containers are made from bamboo fiber and lined with a corn-based PLA. They are certified compostable by the Biodegradable Products Institute for composting in commercial facilities. This retail expertise enables customers to make informed decisions while ensuring product compatibility with their specific applications.

Technical expertise includes comprehensive composting infrastructure knowledge and disposal guidance that supports customer success with biodegradable solutions. Compostable takeout containers that meet ASTM standards for commercial composting can be sent to a commercial composting facility for disposal. Compostable to go containers that are certified by BPI, TUV, or CMA, can go to a commercial composting facility. This educational support addresses the practical challenges associated with implementing biodegradable packaging programs.

Eco Quality Inc.: Direct-to-Consumer Solutions

Eco Quality Inc. has established specialized expertise in direct-to-consumer biodegradable container sales through comprehensive product selection, competitive pricing, and customer service that addresses the needs of smaller businesses and individual consumers seeking sustainable packaging alternatives. Ecofriendly, recyclable, compostable and biodegradable take out containers demonstrates the comprehensive approach to environmental responsibility.

Product diversity encompasses multiple biodegradable materials and configurations that address diverse customer requirements and budget considerations. Compostable Biodegradable Take Out Food Containers with Clamshell Hinged Lid Microwaveable, Disposable Takeout Box to Carry Meals Togo [6×6, 9×9, 9×6] Compostable Souffle Portion Cup with Lid, Disposable Biodegradable Tasting Sample Cups, Sauce Ramekin Cup , Condiment Cup, Jello Shot Cups This product range demonstrates capability in serving varied application requirements across different food service segments.

Manufacturing Capabilities and Technology Integration

American biodegradable takeout container manufacturers leverage sophisticated processing technologies including molded pulp forming, advanced thermoforming, and innovative material science that enable production of high-performance sustainable containers. These manufacturing capabilities encompass comprehensive quality control systems, automated production lines, and integrated testing protocols that ensure consistent performance while maintaining cost competitiveness essential for commercial success.

Innovation leadership includes continuous investment in research and development, sustainable material advancement, and processing optimization that maintains competitive advantages while addressing evolving customer requirements and regulatory standards. Advanced manufacturing facilities integrate energy-efficient systems, waste minimization technologies, and comprehensive environmental management that support sustainability objectives while optimizing operational efficiency.

Supply chain integration encompasses domestic raw material sourcing, established supplier relationships, and logistics optimization that ensures reliable performance while supporting local economic development and reducing transportation-related environmental impacts. This domestic focus provides strategic advantages including shorter lead times, better quality control, and reduced supply chain risks compared to international alternatives.

Future Growth Prospects and Industry Outlook

The American biodegradable takeout container manufacturing industry continues expanding through increasing state-level plastic reduction mandates, growing consumer environmental consciousness, and corporate sustainability commitments that create favorable market conditions for continued growth. Industry analysts project significant market expansion driven by regulatory requirements, customer preferences, and technological advancement that support sustainable packaging adoption across diverse market segments.

Technology advancement continues driving industry evolution through improved biodegradable materials, enhanced processing capabilities, and innovative product features that create competitive advantages while addressing evolving customer requirements and environmental regulations. Investment in research and development, manufacturing capacity expansion, and market development supports continued industry growth while advancing sustainability objectives and circular economy principles.

Market consolidation trends create opportunities for scale advantages while requiring continued innovation and customer focus to maintain competitive positioning in dynamic markets characterized by evolving regulations, changing customer preferences, and increasing competition from both domestic and international suppliers seeking market share in the growing sustainability segment.

Conclusion: American Leadership in Sustainable Packaging Innovation

The leading biodegradable takeout container factories in the USA represent the convergence of environmental responsibility, manufacturing excellence, and market responsiveness that positions American industry as a global leader in sustainable food packaging solutions. These companies demonstrate comprehensive capabilities in material science, manufacturing technology, and customer service while maintaining commitment to authentic environmental stewardship and operational excellence.

Their collective leadership drives continuous advancement in biodegradable materials, manufacturing processes, and application development that benefits the global food service industry while supporting broader environmental objectives and circular economy principles. Through continued investment in domestic manufacturing capabilities, sustainable technology development, and customer service excellence, American manufacturers ensure continued market leadership while contributing to more sustainable food service operations and environmental protection.

Success in this rapidly evolving industry requires comprehensive capabilities in sustainable materials science, advanced manufacturing technology, regulatory compliance, and customer collaboration that create competitive advantages while supporting long-term environmental and business sustainability objectives essential for continued growth in increasingly demanding markets prioritizing authentic environmental performance.