China has established itself as the global powerhouse for biodegradable food container manufacturing, leveraging advanced technology, sustainable material innovation, and comprehensive production capabilities to meet the surging worldwide demand for eco-friendly packaging solutions. As we enter 2025, the transition to biodegradable packaging is no longer optional—it’s a global necessity. The top biodegradable food container manufacturers in China are spearheading this green revolution by offering innovative, affordable, and sustainable alternatives to single-use plastics.

China’s Leadership in Sustainable Food Packaging

The Chinese biodegradable food packaging industry has experienced remarkable growth through strategic investment in sustainable technologies, comprehensive regulatory support, and innovative material science that addresses global environmental challenges. The global market for biodegradable food containers is growing rapidly due to environmental policies, consumer awareness, and technological innovation. A report by Future Market Insights forecasts a CAGR of 10.8% in the biodegradable food packaging industry from 2025 to 2035.

Chinese manufacturers have achieved competitive advantages through integration of advanced processing technologies, sustainable raw material sourcing, and comprehensive quality management systems that ensure consistent performance while maintaining environmental responsibility. China’s sustainable food packaging sector is booming—and these 10 companies represent the best of innovation, compliance, and scale. Whether you’re a startup looking to reduce plastic usage or a global chain sourcing compostable packaging, suppliers like Bioleader®, Sunkea, and YJS provide scalable solutions tailored for 2025 and beyond.

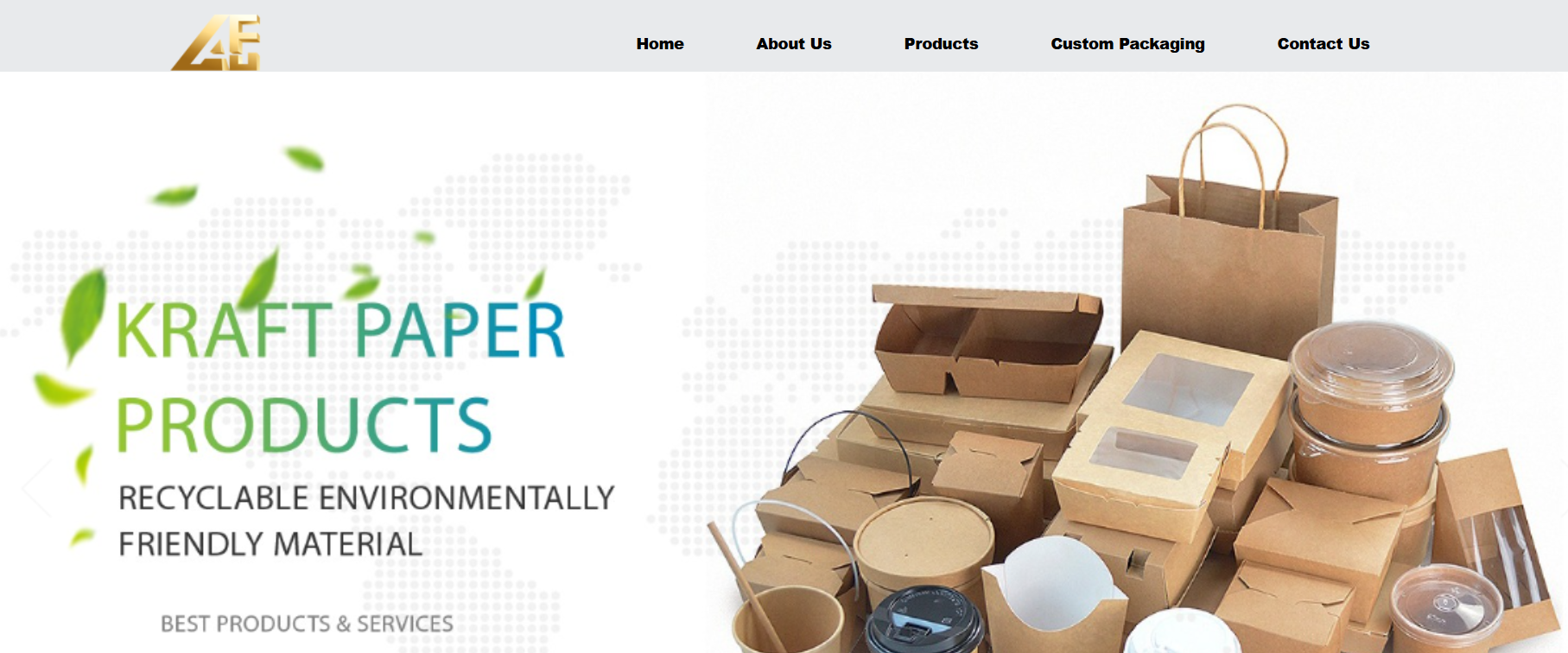

The industry ecosystem encompasses diverse materials including sugarcane bagasse, cornstarch-based PLA, kraft paper, bamboo fiber, and innovative composite formulations that address varied application requirements while maintaining authentic biodegradability and environmental performance. Cornstarch-based PLA and CPLA: Made from fermented plant starch; PLA is transparent and suitable for cold foods, while CPLA withstands higher temperatures, making it ideal for utensils and hot food containers. Both degrade completely within industrial composting environments in 60–180 days. Kraft Paper: A recyclable, biodegradable, and versatile packaging material often used for food wraps, boxes, and bags. Kraft paper packaging is compostable within about 60 days when uncoated or coated with biodegradable materials.

Bioleader: Innovation Excellence and Global Recognition

Bioleader has established itself as China’s premier biodegradable food container manufacturer through comprehensive specialization in sustainable packaging solutions, advanced production capabilities, and unwavering commitment to environmental stewardship. Company Overview: Bioleader® is a leading plastic-free food packaging manufacturer based in Fujian, China. Established in 2012, the company has rapidly gained global recognition for producing 100% compostable packaging, including bagasse food containers, cornstarch tableware, PLA cold cups, and kraft pa

Manufacturing excellence encompasses advanced production capabilities utilizing state-of-the-art molded pulp technology and comprehensive quality control systems. Overview: As a top-tier manufacturer and innovator in bagasse food containers, Bioleader® sets the standard in Asia and exports globally. Specializing in sugarcane-based, plant-fiber molded pulp containers, Bioleader® combines sustainability with scalable production.

Production capacity and technological advancement enable significant manufacturing volume while maintaining quality consistency. Competitive pricing for global wholesale. Flexible customization (OEM/ODM). Advanced automated pulp molding production lines. Bulk capacity: 100+ containers/month.

Certification excellence demonstrates comprehensive compliance with international environmental and food safety standards. The company holds international certifications such as BPI, OK Compost, and FDA approvals. Its products have significantly reduced plastic usage worldwide, particularly in foodservice sectors.

Environmental leadership extends beyond product manufacturing to encompass sustainable production processes and comprehensive lifecycle management. Case Study: Bioleader’s commitment to PFAS-free, microwave-safe bagasse containers shows how a responsible biodegradable food container manufacturer can lead by example. Its products meet FDA and EU standards, and its production facility is powered by energy-efficient systems to reduce emissions.

Lesui Packaging: Large-Scale Integrated Manufacturing

Lesui Packaging represents large-scale biodegradable food container manufacturing capabilities through comprehensive integrated operations, advanced German technology, and significant production capacity that serves global markets. Lesui is a leading eco-friendly food packaging manufacturing company specializing in the R&D, sales, and production of biodegradable food packaging, with our factory exceeds 60,000 square meters and annual output over 60.000 tons. OEM/OEM is Available. Contact Us Now!

Manufacturing infrastructure encompasses comprehensive research and development capabilities alongside advanced production facilities. Lesui company is a research and development, production and sales into a integrated biodegradable food packaging manufacturer. Our state of the art manufacturing Facilities across the region with the latest German technology extend to exceed 60,000 square meters in area. With the annual output reaches more than 60.000 tons, and the annual output value is over 600 million yuan.

The company’s integrated approach encompasses comprehensive product development, manufacturing optimization, and quality assurance that ensures consistent performance while maintaining cost competitiveness essential for serving diverse international markets requiring reliable supply chain performance and sustainable packaging solutions.

Luzhou Pack: Established Market Leadership

Luzhou Pack has achieved recognition as one of China’s established biodegradable food container manufacturers through over two decades of industry experience, comprehensive certification standards, and commitment to plant fiber technology innovation. Luzhou Pack was established by Shaoneng Group Co., Ltd. (Stock No. 000601.SZ) in Jan 16, 2001. For 20+ years, we have committed to selling biodegradable plant fiber products, providing plant fiber technology consultation and designs.

Manufacturing excellence encompasses comprehensive research and development capabilities alongside large-scale production systems that support global market development. With highly innovative R&D team, great scale production lines and all-rounded certification (e.g. BRC A+, BSCI, etc), we have become prime manufacturer in China and even globally.

Certification leadership provides comprehensive validation of environmental performance and product safety characteristics. What’s more, there’s no need to worry about the biodegradability and compostability of our products, for all of them comply with strict standard of BPI ASTM D6400 and/or D6868, OK COMPOST HOME, EN13432, etc.. To sum up, let’s work together with ease in mind, we have great confidence to help growing your business!

Product specialization focuses on bagasse tableware and comprehensive sustainable packaging solutions that address diverse market requirements while maintaining authentic environmental performance and cost competitiveness essential for commercial success across international markets.

Sunkea: Paper-Based Container Expertise

Sunkea has established comprehensive expertise in paper-based biodegradable food containers through strategic focus on kraft packaging, international market development, and comprehensive certification standards that support global export capabilities. Overview: Founded in 2008, Sunkea has built a solid international reputation for exporting disposable food packaging, especially paper cups and kraft containers. Certified with FSC, BRC, and FDA. Exports to over 70 countries. Fast turnaround for custom designs.

The company’s market position reflects established international presence and comprehensive customer service capabilities that address diverse regional requirements while maintaining consistent quality standards and regulatory compliance essential for global market success and customer satisfaction across varied application segments.

Green Olive: Innovation and Patent Leadership

Green Olive represents innovation leadership in biodegradable food container manufacturing through comprehensive research and development capabilities, patent portfolio development, and specialized focus on advanced lid technologies. Green Olive is the largest Biodegradable food container manufacturer in China with strong R&D capabilities, we have registered several patents in China and will continue to develop new innovative eco lids with affordable price to replace single use plastic cup lids.

Technical excellence encompasses advanced product development capabilities that address specific performance challenges in sustainable packaging applications. All of our compostable coffee cup lids are 100% biodegradable, compostable, and sustainable, water-proof,heat resistant and spilling proof due to advanced formula and special tight fitting design, perfectly suited for hot cold drink cups &cold drink cups and takeaway coffee.

Quality assurance and certification demonstrate comprehensive compliance with international standards while supporting global market access. At the moment our products had passed FDA, BPI, EN13432, ASTM6868, OK-Compost, and China test reports.

Qingdao Lafu: Specialized Bagasse Manufacturing

Qingdao Lafu has developed specialized expertise in sugarcane bagasse food containers through focus on high-performance characteristics, thermal resistance, and rapid biodegradability that addresses demanding food service applications. Main Products: Qingdao Lafu manufactures sugarcane bagasse tableware and compostable food containers known for strength, heat-resistance, and rapid biodegradability. Located in Qingdao, Shandong Province, the company has around 150 employees and is recognized for its commitment to sustainability.

The company’s manufacturing capabilities focus on optimizing material properties and processing techniques that achieve superior performance characteristics while maintaining cost competitiveness essential for serving diverse market segments requiring reliable sustainable packaging solutions with proven environmental performance and operational effectiveness.

Packoi Printing: Customizable Packaging Solutions

Packoi Printing represents comprehensive customization capabilities in biodegradable food packaging through specialized focus on recyclable printed products, flexible design services, and established manufacturing experience serving global markets. Main Products: Specializes in customizable recyclable packaging products, including biodegradable printed boxes and bags. Location and Scale: Founded in 1998, Packoi Printing operates in Guangdong Province with over 200 employees, catering to various global markets.

The company’s established market position reflects comprehensive experience in addressing diverse customer requirements while maintaining manufacturing efficiency and quality standards essential for competitive positioning in demanding global markets requiring customized sustainable packaging solutions.

Kunze: Molded Pulp Technology Leadership

Kunze has achieved recognition in molded pulp packaging manufacturing through specialized expertise in advanced processing technologies, comprehensive product development capabilities, and integration of sustainable materials including PLA-based solutions. Main Products: Kunze specializes in molded pulp packaging, biodegradable paper boxes, and PLA-based products. Location and Scale: Based in Liaoning Province, the company employs over 200 professionals and operates state-of-the-art production lines.

Manufacturing capabilities encompass advanced processing equipment and comprehensive technical expertise that enable production of complex molded pulp configurations while maintaining dimensional accuracy and structural performance characteristics essential for demanding food service applications requiring reliable container solutions.

Suneco: Takeout and Catering Specialization

Suneco has developed specialized focus on biodegradable paper containers and molded fiber trays optimized for takeout and catering industry applications, addressing the specific requirements of food service operations requiring reliable sustainable packaging solutions. Main Products: Suneco provides biodegradable paper containers and molded fiber trays widely used in takeout and catering industries.

The company’s market specialization enables focused product development and application optimization that addresses the unique operational requirements of food service businesses while maintaining cost competitiveness and environmental performance essential for commercial success in competitive market segments.

Market Excellence and Quality Standards

Leading Chinese biodegradable food container manufacturers have established comprehensive quality management systems that ensure international compliance while supporting competitive advantages through continuous innovation and customer service excellence. Certification standards encompass comprehensive international requirements including BPI, ASTM, FDA, and European composting standards that validate authentic environmental performance while supporting global market access.

Key Advantages of Leading Chinese Manufacturers:

-

Advanced Material Technology: Comprehensive expertise in bagasse, PLA, kraft paper, and innovative composite formulations

-

Production Scale: Large-volume manufacturing capabilities with consistent quality and delivery performance

-

International Certification: BPI, ASTM, FDA, and European compliance ensuring global market access

-

Customization Services: Comprehensive design, printing, and branding capabilities for market differentiation

-

Cost Competitiveness: Optimized manufacturing processes delivering competitive pricing without compromising quality

-

Environmental Leadership: Authentic sustainability commitment with verified biodegradability and compostability performance

-

Global Distribution: Established export networks and supply chain capabilities serving international markets

-

Innovation Excellence: Continuous research and development driving advancement in sustainable packaging technologies

Quality control encompasses comprehensive testing protocols that validate biodegradability characteristics, food safety compliance, and structural performance under intended use conditions. Manufacturing consistency ensures reliable supply chain performance while maintaining environmental authenticity and cost competitiveness essential for successful market penetration and customer satisfaction.

Supply chain integration includes domestic raw material sourcing, established supplier relationships, and logistics optimization that supports reliable delivery performance while maintaining cost advantages and environmental benefits associated with reduced transportation impacts and regional economic development.

Future Growth and Industry Outlook

The Chinese biodegradable food container manufacturing industry continues expanding through increasing global environmental awareness, regulatory support for sustainable packaging, and technological advancement that creates favorable conditions for continued market growth and innovation development. Industry consolidation trends support scale advantages while requiring continued innovation and customer focus to maintain competitive positioning in dynamic global markets.

Investment in research and development, manufacturing capacity expansion, and international market development supports continued industry growth while advancing sustainability objectives and circular economy principles. Technology advancement continues driving material performance improvement, processing efficiency optimization, and application development that creates competitive advantages while addressing evolving customer requirements and environmental regulations.

Market expansion opportunities include emerging applications, geographic diversification, and collaborative partnerships that leverage complementary capabilities while supporting mutual growth objectives and environmental stewardship throughout the global packaging supply chain ecosystem.

Conclusion: China’s Leadership in Sustainable Food Packaging Innovation

The top 10 biodegradable food container manufacturers in China represent the convergence of environmental responsibility, manufacturing excellence, and innovation leadership that positions Chinese industry as the global standard for sustainable food packaging solutions. The top biodegradable food container manufacturers in China are spearheading this green revolution by offering innovative, affordable, and sustainable alternatives to single-use plastics. Businesses that align with these solutions today will not only reduce their carbon footprint but also gain a competitive edge in tomorrow’s environmentally conscious marketplace.

Their collective leadership drives continuous advancement in biodegradable materials, manufacturing processes, and application development that benefits global food service industries while supporting broader environmental objectives and circular economy principles. Through continued investment in research and development, production capacity expansion, and international market development, Chinese manufacturers ensure continued market leadership while contributing to more sustainable food packaging solutions worldwide.

Success in this rapidly evolving industry requires comprehensive capabilities in sustainable material science, advanced manufacturing technology, regulatory compliance, and customer collaboration that create competitive advantages while supporting long-term environmental and business sustainability objectives essential for continued growth in increasingly demanding global markets prioritizing authentic environmental performance and operational excellence.