Introduction

As a factory specializing in CPET baking trays, we design oven-safe disposable trays that go from -40℃ cold chain to 220℃ oven without deformation. Our clients in ready meals, airline catering, and QSR delivery standardize on oven-safe disposable baking trays to cut waste and simplify operations.

In this article, we explain why CPET can be used in ovens, compare materials for procurement, and share how our factory supports compliant, scalable supply. If you are evaluating CPET baking trays for multi-market distribution, this guide is for you.

What Makes CPET Baking Trays Oven-Safe?

First, the material itself. CPET is crystalline polyethylene terephthalate, a crystallized and modified form of PET engineered via controlled heating to form a dense crystalline structure. This tight molecular arrangement resists chain mobility at elevated temperatures, so properly made CPET baking trays maintain integrity from -40℃ to 220℃ (-40℉ to 428℉). That wide CPET temperature resistance underpins “frozen to oven” performance.

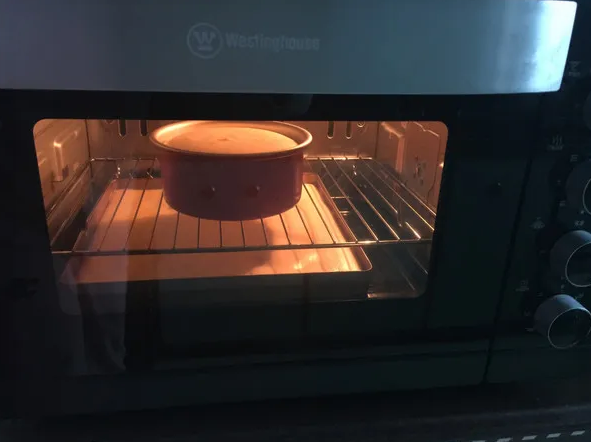

Second, thermal stability in real ovens. Conventional ovens combine conduction from the rack, convection from hot air, and radiant heat from elements. CPET’s semi‑crystalline morphology balances rigidity with toughness, so trays keep shape without softening or sagging under pan weights. In bake cycles, oven-safe disposable trays made from CPET distribute heat uniformly enough for even reheat while resisting edge curl.

Third, safety and compliance. CPET is chemically stable at baking temperatures and does not release harmful gases when processed and used correctly. Our CPET baking trays are produced under ISO 9001 quality management and meet major food‑contact frameworks such as FDA and EEC/EU food‑contact requirements.

Our factory designs resin recipes, crystallization profiles, and mold cooling to lock in dimensional stability. The result: CPET baking trays that are truly oven‑ready, microwave‑capable, and fit automated lines.

CPET vs Other Baking Trays: A Procurement Comparison

Selecting the right heat-resistant disposable trays is both a technical and commercial decision. Below is a quick view comparing CPET vs aluminum foil baking trays, PP, and PLA for B2B use.

| Attribute | CPET baking trays | PP trays | PLA trays | Aluminum foil trays |

|---|---|---|---|---|

| Typical temperature range | -40℃ to 220℃ | -20℃ to 120℃ | 0℃ to 50–60℃ | -40℃ to 250℃+ |

| Oven suitability | Yes, conventional and microwave | Not for ovens | Not for ovens | Conventional ovens only; not microwave‑safe |

| Frozen-to-oven use | Yes, no pre‑thaw needed | Risk of warping/cracking | Not suitable | Yes, but avoid microwaves |

| Cold-chain compatibility | Excellent | Moderate | Poor | Excellent |

| Per‑unit total cost | 15–20% lower than foil in typical programs | Lower than CPET | Lower than CPET | Highest landed cost (often) |

| Branding/printing | In‑mold color, embossing, lidding films | Limited at high heat | Limited | Limited; labels required |

| Environmental pathway | Widely recyclable where PET streams exist | Recyclable (PP streams) | Industrial composting possible | Recyclable aluminum, higher energy in smelting |

| Cross‑border compliance | Strong global acceptance; FDA/EU food contact | Broad, but no oven use | Variable; temperature limits | Broad, but microwave restriction |

For B2B bakery and ready-meal lines needing heat-resistant disposable trays, CPET provides the widest usable window. In many rollouts, CPET vs aluminum foil baking trays shows a 15–20% system cost advantage when you factor branding, lidding, denesting, and microwave compatibility.

CPET baking tray buyer operation scenario

Ready meals and central kitchens. CPET baking trays for ready meals enable a single SKU to cover blast freezing, MAP sealing, chilled distribution, and same‑tray baking. Buyers gain fewer changeovers and fewer breakages from frozen handling.

Airline catering. Airline food packaging trays must be freezer‑capable, galley‑oven safe, and compact on trolleys. CPET baking trays keep lids sealed after altitude cycles and reheat evenly on board, reducing replate labor.

QSR/virtual brands and delivery. Operators use frozen to oven baking trays to maintain texture from store back‑freezers to in‑store ovens, with consistent dwell times and minimal cleanup. CPET supports tamper‑evident lidding and SKU‑level branding without label failure.

Bakery wholesale. Par‑baked items ship frozen and finish‑bake in‑store using the same oven-safe disposable trays, keeping crust quality and pan geometry. This also improves shelf presentation and reduces tray returns.

A recent case: a multinational ready‑meal brand adopted our CPET baking trays across three plants. Logistics damages fell 30%, and customs clearance efficiency improved by 50% due to harmonized documentation and HS coding supported by our Vietnam overseas warehouse. That’s the one‑tray solution across storage, heating, and transport that procurement teams look for.

How to Use and Buy CPET Trays Correctly

Usage tips for kitchens and lines:

- Preheat ovens to ≤220℃ and follow specified dwell times. Our CPET baking trays tolerate the full range but avoid exceeding limits.

- Vent lidding films by piercing a small hole before baking to release steam and preserve seal integrity.

- Do not let trays touch exposed heating elements or open flames. Place on racks or sheets and avoid broil mode.

Procurement checkpoints to avoid pitfalls:

- Verify crystallization quality. Ask suppliers for crystallinity control data and deformation tests at 220℃ under load.

- Confirm certifications and DoC packs. Our factory provides a complete certification file, including migration test reports and ISO 9001.

- Check customization and automation fit. We support custom dimensions, embossing/LOGO, easy denest rims, and film/lid matching. Free samples are available for line trials.

Key Certifications for Cross-Border Procurement

- FDA food‑contact compliance for PET‑based materials.

- EU/EEC food‑contact compliance (e.g., Regulation (EC) No 1935/2004 and EU 10/2011 for plastics), with overall and specific migration testing.

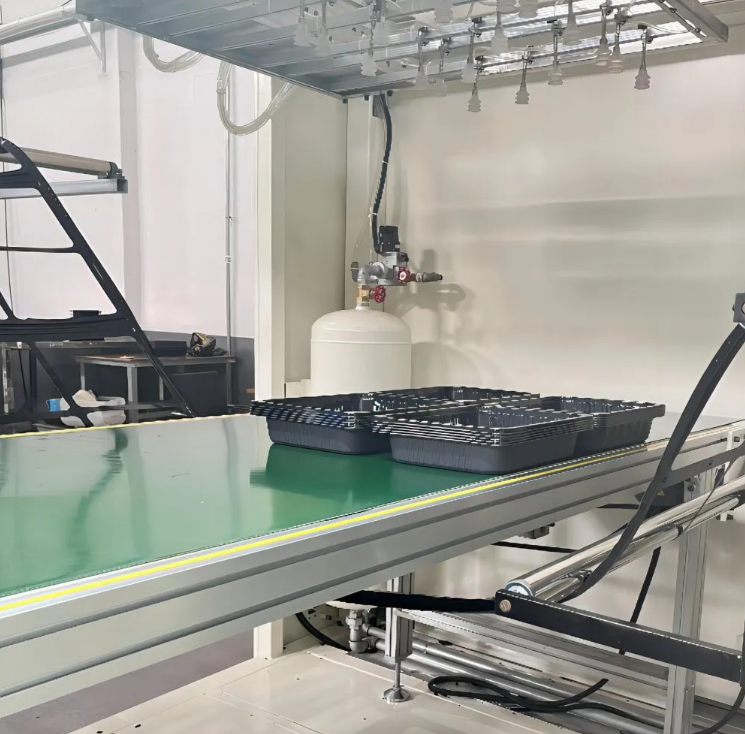

- ISO 9001 quality management for consistent production and traceability. Our factory maintains intelligent production lines with in‑line vision inspection and offers buffer stock from our Vietnam overseas warehouse to accelerate regional fulfillment of oven-safe disposable trays.

FAQ and Next Steps

Q1: Are CPET baking trays compostable or recyclable? A: Standard CPET baking trays are recyclable in PET streams where available. Some modified CPET products can be formulated to meet EN 13432 compostability under industrial conditions; if you require this, we can provide formulations and a carbon‑footprint report.

Q2: What’s the minimum order quantity (MOQ) for custom CPET baking trays? A: Our MOQ is 5,000 sets. We provide samples within 3 days and deliver mass production within 20 days, with safety stock options from our overseas warehouse.

Q3: Can CPET trays be used in both conventional ovens and microwaves? A: Yes. CPET baking trays work in both. For microwave use, remove any metal lids; our products undergo dual‑use validation.

Ready to evaluate a unified packaging format that reduces SKUs and total cost? Click to get the CPET product manual plus free samples. As a custom CPET baking trays supplier, we provide FDA/EU documentation, a cross‑border clearance guide, and low‑risk pilot orders. If you source wholesale heat-resistant disposable trays across regions, our factory will engineer the right tray, film, and logistics plan to scale.

Additional procurement notes

- Our CPET baking trays are compatible with common denesting magazines and high‑speed sealing equipment. This keeps oven-safe disposable trays flowing smoothly on automated lines.

- We support private molds for unique footprints, multi‑compartment designs, and color coding for portfolio differentiation.

- Ask about our “frozen to oven baking trays” SKUs pre‑matched with peelable anti‑fog lidding for display‑ready merchandising.

By choosing CPET baking trays, buyers get oven reliability, freezer strength, and global compliance in one material—turning packaging into a lever for speed, safety, and margin.